How Do Embedded Systems Enhance Functionality in Flow Transmitter Boards?

What is the Role of Embedded Systems in Flow Transmitter Circuit Boards

What Is a Flow Transmitter Circuit Board and How Does It Work?

A flow transmitter circuit board plays a vital part in today’s industrial flow measurement setups. It acts as the link between actual flow sensors and digital control setups. The board takes in analog signals from different flow sensors—like electromagnetic, ultrasonic, or vortex types. Then, it turns those signals into digital data using built-in analog-to-digital converters (ADC). This change makes it possible to clearly understand and share flow details with oversight systems.

The circuit board usually has key parts. These include amplifiers that strengthen faint signals. It also has signal conditioners to remove noise. Plus, there are microcontrollers or microprocessors to run control tasks. Communication links like RS485, HART, or MODBUS are built in too. They allow smooth sending of handled data to main monitoring spots. All these elements team up to deliver exact measurements and solid system connections in industrial uses.

Why Are Embedded Systems Essential in Flow Transmitter Boards?

Embedded systems form the core of current flow transmitter boards. They let these boards run with strong efficiency, exactness, and independence. A main job they do is handle sensor data right away. This means quick reactions to shifting flow situations without outside computing waits. Such ability matters a lot in fast-changing places like oil refineries or water treatment sites.

Embedded systems also add smart digital adjustment and fix-up methods. These boost measurement exactness even with changes in surroundings or sensor shifts. Special signal handling and fix-up models beat those from local rivals. As a result, they achieve ±0.1% exactness in tough spots.

On top of that, these systems focus on low energy use. This is key for jobs that need long runs in far-off or tough-to-reach areas. Things like smart rest modes and flexible speed changes keep work smooth while saving power.

Key Functional Enhancements Enabled by Embedded Systems

How Do Embedded Systems Improve Signal Processing?

Embedded systems greatly boost the signal handling skills of flow transmitter circuit boards. They use strong digital filter methods to cut out electromagnetic disruptions and noise from basic sensor signals. So, only the most reliable and steady data gets handled.

Signal boosting and changing happen with care. This uses built-in ADCs and adjustable gain amplifiers (PGAs). They allow precise tweaks to sensitivity for certain job needs. What’s more, the built-in software can shift detection levels or adjustment lines based on live surroundings like heat or pressure. This keeps steady work in different settings.

For instance, ICwalk’s H8250FZ float flow transmitter board gives high measurement exactness. It does this by using advanced signal handling tech to wipe out disruption signals well. Thus, it ensures steady output even in hard industrial spots.

What Communication Capabilities Are Enabled by Embedded Technology?

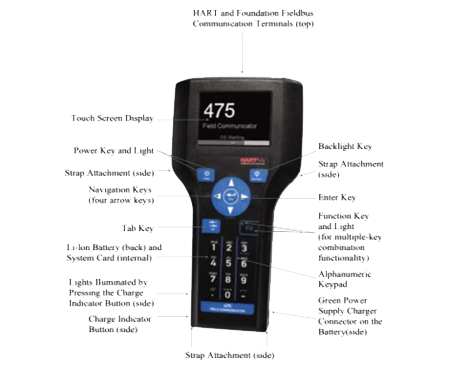

Embedded systems give flow transmitter boards tough and flexible communication skills. These are needed for industrial automation. They cover standard protocols like 4–20 mA current loops, RS485 serial links, MODBUS RTU, and HART. All this allows easy joining with SCADA systems and spread-out control systems (DCS).

Lots of new boards also have wireless parts for IoT (Internet of Things) uses and far-off watching. Live checks, warnings, and adjustment updates can go straight to cloud spots or main control areas.

ICwalk’s E4000 serisi provides varied output choices. These include 4–20 mA current output and digital communication protocols like HART and MODBUS. This makes smooth links to control and monitoring systems possible.

How Do Embedded Systems Support Power Efficiency?

Power saving is a big design point in embedded flow transmitter boards. Built-in microcontrollers with low-energy modes let the device go into wait or rest states when not active. This cuts energy use a lot. These microcontrollers can wake up on set triggers. Examples include flow movement or set times to start work again.

Smart power control units can adjust voltage based on task needs and surroundings. For example, if a process line sits idle, the board can lower its run speed or turn off unneeded parts until required once more.

This method not only extends the device’s life but also suits battery-run jobs or spots without main power—like in far oil fields or farm watering systems.

Design Considerations in Flow Transmitter Circuit Boards with Embedded Systems

What Are the Hardware Components Typically Used?

To back up detailed tasks while keeping dependability, embedded flow transmitter boards include several main hardware parts:

- Microcontroller or Microprocessor Unit (MCU/MPU): Handles running control tasks, operating methods, managing communication links, and guiding all system jobs.

- Analog-to-Digital Converters (ADC): Turn analog sensor signals into digital form with high detail for exact handling.

- Voltage Regulators and Power Management ICs: Provide steady voltage for delicate electronic parts.

- Memory Modules: Hold firmware, setup options, and past data for checks or adjustment needs.

- Communication Ports: RS485 transceivers, HART modems, or wireless parts for easy joining with outside networks.

How Does Software Integration Affect Performance?

Built-in firmware has a central role in forming the full performance of a flow transmitter board. Firmware updates can happen from afar or on-site to grow features without hardware changes. This adds backing for new sensors, betters method speed, or fixes issues.

By using real-time operating systems (RTOS), the built-in software manages multiple tasks well. It allows side-by-side work like data gathering, signal handling, communication care, and user display updates. All this happens without clashes or waits.

In ICwalk products like the H880BR vortex flowmeter board, features such as Real-time Automatic Gain Control (RAGC) and Self-adaptive Spectrum Filtering (SSP) show how built-in software betters performance. It adapts quickly to changing flow traits.

Applications Across Industries Supported by Embedded Flow Transmitter Boards

Where Are These Boards Commonly Used?

Embedded flow transmitter boards see wide use in many fields thanks to their flexibility and exactness:

- In water treatment plants, they track distribution speeds to secure best cleaning and resource sharing.

- HVAC systems in business buildings use them to control airflow for steady comfort in the environment.

- Oil & gas pipelines depend on exact flow checks for safe running and right billing.

From oil & gas to pharmaceuticals, power making, and sea platforms, our boards find broad use in tough industrial jobs. They help clients gain market wins with trust.

How Do Industry Requirements Shape Board Design?

Each field sets special limits that form the design of flow transmitter circuit boards. For example:

- Tough surroundings need strong covers with IP-rated seals against dampness, dirt, and harsh chemicals.

- Electromagnetic Interference (EMI) protection must go in for setups near big machines or power lines.

- Following rules like ISO ensures dependability and tracking via built-in data recording and adjustment checks.

Our auto production and test systems promise solid work for every board—even in big groups. This fits them for key sectors like pharmaceuticals.

Spotlight on ICwalk’s Flow Transmitter Board Solutions

What Makes ICwalk’s Flow Transmitter Boards Stand Out?

At ICwalk, we have put over 16 years into creating top-notch solutions that change what’s doable in industrial tools. We are a Beijing-based high-tech firm started in 2007. Our goal is to transform industrial automation with exact tools and smart process control answers.

Our flow transmitter circuit boards have embedded systems made just for live signal handling across flow types—electromagnetic, ultrasonic, vortex, and rotameter kinds. Our items include tuned firmware that backs live signal handling and industrial communication rules like 4–20 mA output or RS485 serial links.

With owned methods able to hit ±0.1% exactness in harsh spots, our answers steadily do better than local choices.

How Can ICwalk Products Be Integrated into Existing Systems?

Our part-based design idea makes sure our items join easily into old systems and new automation setups. If your job needs backing for HART protocol devices or fit with MODBUS RTU over RS485 networks, our boards give simple plug-in ease plus deep tweak options.

We have given 200+ custom answers for 800+ makers. We shape every part from sensor matching needs to surroundings toughness. This fits our answers for special jobs like tiny-flow checks in labs or big-scale watching in city projects.

Sık Sorulan Sorular

Q: What is the difference between a flow transmitter and a flow sensor?

A: A flow sensor spots the real movement of fluid, while a flow transmitter handles that signal into clear data using embedded electronics to share with control systems.

Q: Can a flow transmitter board be used with any type of fluid?

A: Most boards work with liquids or gases but need matching with right sensors based on the fluid’s traits like thickness, heat, or harmfulness.

Q: How do I know if my flow transmitter board needs calibration?

A: Clues include uneven readings, shifts over time, or not matching reference tools; steady adjustment keeps exactness going especially in ruled fields like pharmaceuticals or water treatment.

İlgili Yazılar

-

How Do Embedded Systems Enhance Functionality in Flow Transmitter Boards?

February 06,2026

-

What Role Does a Level Control Board Play in Transmitter Efficiency?

February 05,2026

-

Integrating Sensors with a Process Control Board Transmitter: Best Practices for Reliable Signal Transmission

January 30,2026

-

Field Communicator vs. Traditional Handheld Tools in Industrial Maintenance

January 29,2026

-

How Is Signal Processing Achieved in Flow Transmitter Circuit Boards?

January 23,2026