What Are the Latest Innovations in Pressure Transmitter Board Technology?

What is a Pressure Transmitter Board and How Does It Work?

Understanding Pressure Transmitter Boards

A Pressure Transmitter Board is a key piece used to shift the physical pressure from gases or liquids into an electrical signal for quick tracking and control. These boards mostly contain a pressure sensing part, signal conditioning circuitry, and analog or digital output links.

The pressure sensing part sees the mechanical push from a fluid or gas and switches it into an electrical signal. This signal then goes through amplification, filtering, and temperature fix circuits. The final result is either an analog signal (like 4–20 mA) or a digital one (such as I²C, SPI, or HART), which monitoring systems or microcontrollers can grasp.

Uses for Pressure Transmitter Boards reach across many fields—from factory automation and energy control to medical gear and aerospace setups.

Why Are Pressure Transmitter Boards Important in Modern Systems?

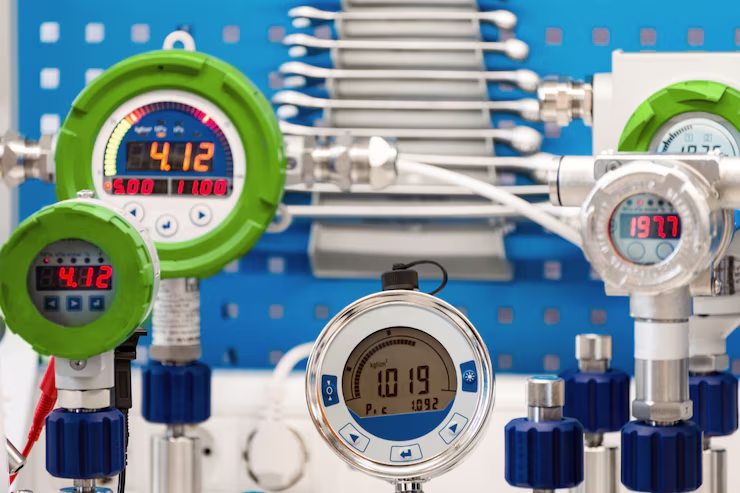

Pressure Transmitter Boards have a big part in making sure key systems stay safe, efficient, and automated. They offer real-time info on how fluids and gases act in pipes, tanks, and machines—details needed to keep things running steady.

Pressure transmitters serve as alerts for risks from high pressure. Their sharpness keeps processes in safe zones, stopping overloads that could wreck gear or cause big failures.

Plus, today’s transmitter boards often tie into IoT setups, allowing far-off checks, data saving, and auto control. This tie-in helps with forward-looking fixes and cuts breaks, lifting overall output.

Key Technological Advancements in Pressure Transmitter Boards

How Are MEMS Technologies Transforming Pressure Transmitter Boards?

Micro-Electro-Mechanical Systems (MEMS) have shifted how Pressure Transmitter Boards get designed by making sensors tiny without dropping sensitivity or trust. These small sensors fit well in spots where space and weight count, like wearable items or tight industrial parts.

MEMS pressure transmitters take less power too, suiting them for battery-based or energy-pulling systems. Their solid make raises lasting power and keeps steady work even in hard spots.

What Role Does Digital Signal Processing Play in Modern Designs?

Digital Signal Processing (DSP) now stands key for raising the sharpness and firmness of Pressure Transmitter Boards. By putting in DSP jobs like noise cut and temperature shift fix, the boards give out very solid data.

Real-time digital tuning ways also aid lasting work by auto-changing the sensor’s reply to outside shifts. Also, digital links like I²C or SPI ease tying to microcontrollers and built-in systems, speeding build times and widening design choices.

How Are Wireless Capabilities Being Integrated into Pressure Transmitter Boards?

Wireless tech such as Bluetooth Low Energy (BLE), Wi-Fi, and LoRa gets added more into Pressure Transmitter Boards. These traits let pressure info travel from a distance, skipping heavy wiring in tricky builds.

Wireless transmitter boards prove useful in moving tools or hard-to-reach places. Battery-run kinds now come with low-power setups, letting long runs without constant checks.

The Role of ICwalk in Advancing Pressure Transmitter Board Technology

What Makes ICwalk‘s Pressure Transmitter Boards Stand Out?

At ICwalk, we supply top Pressure Transmitter Boards that blend sharp sensing parts with firm signal handling systems. Our H3051 line of smart pressure transmitters works with sensors like diffused silicon, single-crystal silicon, PT100, magnetic flap, sapphire, and sputtered thin film types.

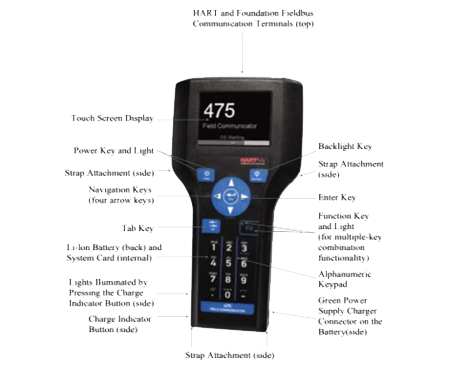

ICwalk transmitter boards get trust from over 800 tool makers in China, backed by wide field tests. Made for bendability, our boards deal with analog (4–20 mA) and digital (HART) outputs, fitting smooth into varied system plans.

Our goods aim for strength—with conformal coating against outside harm, high-power TVS for spike hold, EEPROM with stronger anti-jam build, and full smart self-test tools for no-upkeep runs.

Where Are ICwalk’s Pressure Transmitter Boards Commonly Used?

Industrial Automation Systems

Our H3051 line sees wide use in industrial automation areas to track hydraulic or air pressures in lines.

Environmental Monitoring Applications

We back weather spots and water works by offering sharp air or under-water pressure info.

Medical Equipment Integration

Our boards go into main medical items like breathing aids and drip pumps to keep tight control on air and liquid flow.

Emerging Trends Shaping the Future of Pressure Transmitter Boards

Are AI Algorithms Enhancing Sensor Performance?

Adding artificial intelligence (AI) boosts the self-test and flexible traits of Pressure Transmitter Boards. AI-led self-tuning paths let units fix themselves at start or with condition changes—lowering hands-on work.

Plus, forward-looking checks from old pressure info spot weird bits early, allowing fix-ahead before troubles hit.

How Is Edge Computing Influencing Board Design?

Edge computing changes pressure data handling. By sticking microcontrollers on the board, local checks happen before sending data. This drops wait time and hurries choices—key in fast-need spots like process hold or alert systems.

It cuts bandwidth draw and cloud reliance for daily watch jobs too.

What Materials Are Being Used to Improve Sensor Durability?

Advanced Packaging Techniques

Fresh packing ways use rust-proof stuff like stainless steel or special mixes to shield touchy electronics from wet, dust, and chem hits. Wetted materials and transmitter cases can be chosen appropriately to extend the service life of the pressure transmitter.

High-Stability Substrates

Taking on Silicon-on-Insulator (SOI) bases raises heat firmness and build strength. These stuffs help hold tuning whole over wide heat swings and strain spots.

FAQ

Q: What is the difference between a pressure sensor and a Pressure Transmitter Board?

A: A pressure sensor sees pressure shifts but may lack signal fix skills, while a Pressure Transmitter Board holds circuitry to shift raw signals into handy electrical outputs like voltage, current, or digital form.

Q: Can I use a Pressure Transmitter Board with Arduino or Raspberry Pi?

A: Yes, lots of today’s boards give I²C or SPI talk ways that match microcontroller bases like Arduino and Raspberry Pi, fitting them for test builds and fun projects.

Q: How do I choose the right Pressure Transmitter Board for my application?

A: Weigh things like pressure span needed, output kind (analog/digital), outside conditions (heat, wet), size bounds, power draw, and match with your setup when picking a board.