The Ultimate Guide to Assembling a Temperature Gauge

What’s a Temperature Gauge and How’s It Work?

A temperature gauge is a must-have tool that checks and shows the temperature of a place or thing. It’s a real-time watchdog for all sorts of uses, from factory machines to home appliances. The main job of a temperature gauge is to turn heat energy into easy-to-read data, helping you keep tabs on systems and avoid overheating or freezing issues.

What Are the Key Parts of a Temperature Gauge?

Sensor Element

The sensor’s the heart of any temperature gauge. It picks up temperature shifts and turns them into an electrical signal. Common ones include thermocouples and resistance temperature detectors (RTDs) like PT100 or PT1000, which are super accurate and reliable in all kinds of settings.

Display Mechanism

The display takes the sensor’s signal and makes it readable, either on an old-school dial or a digital screen. Digital displays are often the go-to for their precision and easy-to-read vibe.

Power Supply

Temperature gauges need steady power to run. Depending on the type, they might use batteries, external DC sources, or circuits baked into control systems.

How Do Analog and Digital Temperature Gauges Differ?

Analog gauges use mechanical bits like bimetallic strips or Bourdon tubes to show temperature changes on a dial. They’re simple and cheap but not super precise. Digital gauges, though, lean on electronic sensors and microcontrollers for spot-on readings on an LCD or LED screen. They also pack extras like data logging and remote monitoring.

Why’s a Temperature Transmitter Board a Big Deal in a Temperature Gauge?

What’s the Deal with a Temperature Transmitter Board?

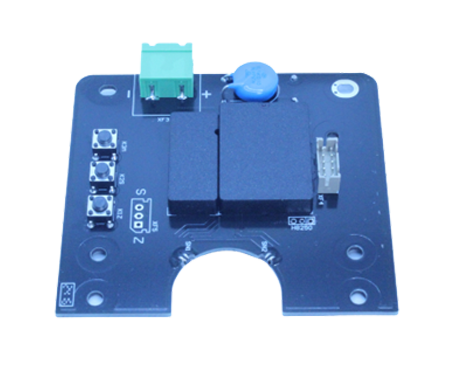

A temperature transmitter board is the middleman between the sensor and the display. It takes raw signals from RTDs or thermocouples and turns them into standard outputs like 4–20mA or digital protocols like HART or DVRT. This makes it play nice with control systems and boosts measurement accuracy.

H649WD series of isolated temperature transmitters converts the ThermoCouple (TC) or Resistance Temperature Detector (RTD) signals from the field, after digital linearization processing, into a temperature-linear 4-20mA current isolated output.

How Does Signal Conversion Make Things More Accurate?

Voltage-to-Digital Conversion

Transmitter boards turn analog voltage signals from sensors into digital ones using analog-to-digital converters (ADCs). This cuts out signal loss over long distances or from electromagnetic interference.

Noise Reduction Features

Fancy transmitter boards use isolation tricks to keep electrical noise low. The module features an isolation voltage of DC1000V, providing reliable electrical isolation for safety and performance in demanding industrial environments. This keeps things steady even in tough conditions.

What Should You Think About When Picking a Transmitter Board?

Key things to consider include whether it works with your sensor (RTD vs TC), output type (analog vs digital), how it’s installed (junction box vs DIN rail), power supply range, environmental toughness, and supported protocols like HART.

Step-by-Step Guide: How to Put Together a Temperature Gauge

What Tools and Stuff Do You Need?

Required Hardware Components

- RTD or thermocouple sensor

- ICwalk temperature transmitter board

- Display unit (digital/analog)

- Power supply (DC10–32V)

- Mounting bracket or enclosure

- Wiring cables

Recommended Safety Equipment

- Insulated gloves

- Safety goggles

- Multimeter for testing

Getting the Sensor and Wiring Ready

Start by figuring out your sensor type—RTD or thermocouple—and make sure it jives with your transmitter board. Strip wire ends carefully and hook them up based on wiring setups: two-wire, three-wire, or four-wire for RTDs.

Setting Up the Temperature Transmitter Board

Mounting the Board Solidly

Pick a spot based on your setup—junction box for tight spaces or DIN rail for modular panels. Screw the board down tig ht using its mounting hole spacing.

Hooking Up Input and Output Wires Right

Connect sensor wires to input terminals, keeping an eye on polarity. Then link output terminals to your control system or display using shielded cables if you can to cut down on noise.

Finishing Up and Testing

Once wiring’s done, fire up the system. Use a multimeter to check if the current output matches expected values at known temps. Tweak calibration settings if needed via onboard controls or software, depending on the model.

Meet ICwalk and Its Temperature Transmitter Board Goodies

Who’s ICwalk and What’s Their Thing?

We at ICwalk are all about high-performance electronic modules for precise environmental monitoring. Our lineup includes top-notch temperature transmitter boards that work with both resistance-based sensors (RTDs) and thermocouples across various industry standards.

Why Pick ICwalk’s Temperature Transmitter Board for Your Project?

Our transmitter boards are built with killer features for industrial reliability:

Key Technical Specs of ICwalk Temperature Transmitter Boards

- Output Accuracy: 0.2%, with an additional cold junction compensation error of 1°C for thermocouples

- Continuous Operating Temperature: -40 to +85°C

- Relative Humidity: 10% to 90% RH

Perks in Assembly, Stability, and Compatibility

Our temperature transmitter boards handle multiple sensor inputs like PT50/PT100/PT500/PT1000 and thermocouples E/J/B/K/N/R/S/T types. Plus, the H3051WD module can measure millivolt signals and resistance signals, making it super versatile for all sorts of industries.

Common Questions About Using a Temperature Transmitter Board in Gauges

How Do I Know If My Transmitter Board’s Calibrated Right?

Check calibration by comparing outputs to known reference temps using certified gear. Some models let you tweak calibration through software.

Can ICwalk’s Boards Work for Both Industrial and Home Stuff?

Yup—our products are tough and flexible enough for heavy-duty factory systems or smaller home automation setups.

What Maintenance Keeps Them Running Long-Term?

Check wiring regularly, recalibrate every so often based on use, clean dust or debris from enclosures, and test output consistency for long-term reliability.

Pro Tips for Boosting Performance and Reliability

How Can You Keep Measurements Super Accurate?

Using Shielded Cables for Clean Signals

Shielded cables cut down on electromagnetic interference that can mess with low-level sensor signals over long runs.

Regular Calibration Check-Ins

Plan to recalibrate every 6–12 months, depending on how critical the use is, to keep accuracy on lock.

What Are Some Tricks for Fixing Weird Readings?

Start with connections—loose wires are often the culprit for funky readings. Use a multimeter to test voltage/current at each step from sensor to transmitter to display. Swap out busted parts quick if issues stick around.

FAQ

Q: What types of sensors do ICwalk temperature transmitter boards support?

A: These transmitters are compatible with a range of standard thermoresistors including PT50/PT100/PT500/PT1000 as well as various thermocouples such as types E/J/B/K/N/R/S/T.

Q: Can I use ICwalk temperature transmitter boards in high-temperature environments?

A: Yup—the continuous operating temperature range is -40°C to +85°C.

Q: Do your temperature transmitter boards support HART communication protocol?

A: Yes—models like H648WD/H649WD/H3051WD offer HART communication capabilities.

Q: Are these temperature transmitter boards easy to install?

A: Yup—our designs feature user-friendly mounting dimensions (Diameter Φ = 44mm; mounting hole spacing D = 33mm) suitable for quick integration into existing systems.

Q: Where can I purchase ICwalk’s temperature transmitter boards?

A: You can order directly from us at our facility located at Room 701, Power Creative A, No.1 Shangdi East Road, Haidian District Beijing 100085 China.

Related Posts

-

Why Over 70% China’s Instrument Manufacturers Chose ICwalk as Their Supplier of Choice

September 25,2025

-

What Role Does the Circuit Board Play in Signal Processing for Transmitters?

September 11,2025

-

What Role Do Level Transmitter Boards Play in Process Automation?

July 24,2025

-

What Role Does Signal Conditioning Play in a Temperature Transmitter Module?

July 10,2025