Temperature Transmitter Board Calibration Guide: Key Methods to Improve Accuracy and Long-Term Stability

Why Calibration Matters for a Temperature Transmitter Board?

Temperature transmitter boards play a key role in industrial setups. They handle exact temperature readings. These units turn signals from sensors, like thermocouples or resistance temperature detectors, into standard outputs such as 4-20 mA or digital signals. Control systems then use these for processing and management. Accurate calibration is vital. It helps these transmitter boards work reliably and stay steady over time. Plus, calibration boosts measurement exactness. It also supports the device’s lasting performance. As a result, you cut down on upkeep and the need for repeated adjustments throughout its life.

This guide looks into why calibrating temperature transmitter boards is important. It covers ways to get precise calibration. And it explains how this affects the ongoing dependability of your tools.

What Are the Temperature Transmitter Board and Its Calibration Requirements?

What Is a Temperature Transmitter Board?

A temperature transmitter board takes sensor signals, such as from thermocouples or RTDs, and changes them into clear temperature info. The transmitter handles the signals from sensors. It adjusts for surrounding conditions. Then, it sends out a standard signal, usually 4-20 mA or digital. Control systems can easily read this output.

These boards are crucial in areas where spot-on temperature checks matter a lot. Think industrial making, power plants, and chemical work.

Why Does a Temperature Transmitter Board Need Calibration?

Calibration makes sure the transmitter board gives true temperature values. This is key for several reasons.

- Accuracy: Good calibration fixes for the built-in traits of sensors, circuit parts, and outside influences that might skew readings.

- Long-Term Stability: Calibration keeps the transmitter steady over years. It stops shifts in the setup that might cause mistakes.

- Compliance: Many fields follow strict quality rules. They demand calibration to keep gear up to code.

What Affects Calibration Accuracy in a Temperature Transmitter Board?

Which Factors Have the Greatest Impact on Calibration Results?

Various elements shape how well calibration turns out.

- Sensor Characteristics: Sensors like RTDs or thermocouples each have their own traits that change the signal. You must factor in differences in how sensors work when calibrating.

- Environmental Factors: Changes in temperature, moisture levels, and electrical noise can harm the precision of a temperature transmitter board.

- Measurement Equipment: The caliber and exactness of the benchmark tool used for calibration matter a great deal in the outcomes.

- Power Supply Stability: Steady power is essential. It keeps output even during use and calibration.

Environmental and Process-Related Influences

Room temperature, air pressure, and site conditions can greatly sway the transmitter’s work. Calibration in a steady setup might miss real-life challenges. That’s why you often need routine on-site checks.

Key Calibration Methods for a Temperature Transmitter Board

Single-Point vs. Multi-Point Calibration

- Single-Point Calibration: This approach fits spots with a tight temperature span. There, the sensor stays consistent. You tweak the transmitter board’s output at just one known temperature point.

- Multi-Point Calibration: When you need top precision, this method covers the full range. It fixes bends and shifts at different temperature spots.

Digital Calibration vs. Hardware Calibration

- Digital Calibration: This uses software to tweak the transmitter board’s output. You adjust it through firmware or setup tools. It’s great for small changes without touching the hardware.

- Hardware Calibration: Here, you make physical changes to parts on the transmitter board. Think trimming resistors or capacitors for the right precision. It’s more lasting and exact, but it takes longer.

How Can Calibration Improve Long-Term Stability of a Temperature Transmitter Board?

Compensation Algorithms and Drift Reduction

During calibration, you add fixing formulas. They handle mistakes from things like temperature shifts and sensor wear. These formulas adjust the sensor’s signal right away. In turn, this keeps the transmitter board reliable and true over the long haul.

Calibration Data Management in Production

Handling data well is key to keeping temperature transmitters dependable long-term. By logging calibration info, makers spot patterns in how things perform. This cuts differences in big runs. It also ensures steady quality across groups of products.

Common Calibration Mistakes and How to Avoid Them

- Using Low-Accuracy Reference Sources: Stick to top-notch calibration gear. That way, you don’t add mistakes in the process.

- Ignoring Warm-Up Time: Transmitters need a moment to settle. Skipping the warm-up leads to off readings.

- Incomplete Calibration Range: Cover the whole temperature span in calibration. Don’t limit it to just the work range.

- Poor Documentation: Write down steps clearly. This aids tracking and doing it again the same way.

- Failure to Verify Calibration: Check the work afterward. Make sure the transmitter board runs true in real use.

Calibration Considerations for Instrument Manufacturers and Sensor Manufacturers

For instrument manufacturers, solid calibration means products hit accuracy goals and follow rules. It also lowers costs for support after sales. That’s because gear comes tuned for best results.

For sensor manufacturers, calibration confirms sensors match transmitter boards well. This eases setup for users. It shortens install time too.

ICwalk Temperature Transmitter Board Solutions and Calibration Advantages

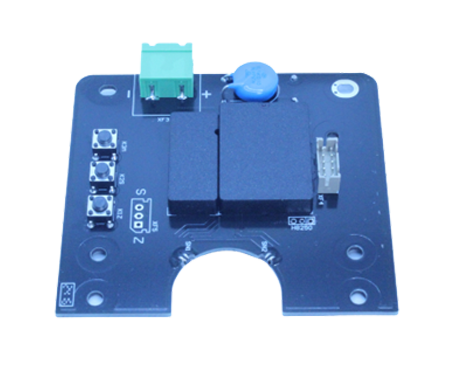

At ICwalk, we focus on creating and building temperature transmitter boards. They deliver outstanding work in tough industrial spots. Our boards, like the H648WD and H649WD series, include many features. These support precise calibration and steady performance over time.

- High-Accuracy Calibration: We build our products for sharp temperature readings. They have built-in cold junction fixes and easy setup choices.

- Advanced Compensation Algorithms: Our special formulas keep ±0.1% accuracy. They handle changing conditions around them.

- Comprehensive Calibration Tools: We provide full software and aids for simple, quick calibration. This fits right into your making line.

- Robust Performance: Our temperature transmitter boards handle harsh industrial tasks. They cope with strong noise and wild temperature swings.

Building High-Accuracy and Stable Instruments Through Proper Calibration

Good calibration is a must for reliable and exact temperature transmitter boards. Using the best methods, makers can boost lasting steadiness. They cut errors too. And they stay in line with field rules. ICwalk‘s top temperature transmitter boards help you get precise readings. They simplify calibration steps. Plus, they ensure solid tool work.

FAQ

Q: How often should a temperature transmitter board be calibrated?

A: How often depends on the job and surroundings. Usually, you calibrate in making. Then, do checks or re-do it now and then in use. This is extra important in fields needing fine work.

Q: What is the difference between sensor calibration and temperature transmitter board calibration?

A: Sensor calibration tunes the sensor on its own. Transmitter board calibration, however, makes sure sensor signals get handled right. It accounts for changes from the board’s processing and circuits.

Q: Can calibration improve the long-term stability of a temperature transmitter board?

A: Yes. Good calibration, paired with fixing formulas, keeps the temperature transmitter board on point over time. It cuts shifts and wear in tough spots.