Key Factors to Consider When Selecting a Process Control Board Transmitter

The Role of a Process Control Board Transmitter

What Is a Process Control Board Transmitter?

A process control board transmitter is a vital electronic tool that acts as a bridge between sensors and factory control setups. Its main job is to turn physical process measurements—such as heat, force, movement, and height—into standard electric signals like 4–20 mA or 0–10 V. Control systems then read these signals for instant watching and choices.

It holds a key spot in factory automation. This device allows precise tracking and management of factors like heat, force, movement, and height. These transmitters keep data reliable for smooth work in areas from making goods to handling chemicals.

Why Is It Important in Industrial Applications?

Process control board transmitters form the core of today’s factory systems. They deliver steady and trustworthy data to programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) setups. This setup allows quick reactions to shifting work conditions.

They guarantee solid data flow to control systems for on-the-spot decisions. By keeping ideal settings and quickly spotting problems, these tools boost both safety and output.

They also work well with many automation standards such as HART and PROFIBUS-PA. This makes them fit for almost any factory arrangement.

Key Performance Criteria When Choosing a Process Control Board Transmitter

What Accuracy and Range Should You Look For?

The success of a process control board transmitter depends on its exactness. Strong measurement precision is vital to cut down work mistakes. Pick transmitters with small errors, best at ±0.1% for important tasks.

The measurement span matters just as much. The transmitter needs to match your process values to prevent waste or overload.

How Does Signal Output Compatibility Affect Integration?

Signal matching is essential for easy fitting into current systems. Most factory setups use standard output types like 4–20 mA or 0–10 V. Making sure your transmitter handles these types allows simple setup with your PLCs or DCS systems.

Fully compatible with mainstream protocols like HART and PROFIBUS-PA, our products match global standards, ensuring smooth integration and easy export.

Matching cuts setup time. It also makes sure the transmitter talks well with your setup.

Is Environmental Durability a Critical Factor?

Factory settings can be rough—with very high or low heat, lots of moisture, chemical contact, or electric noise (EMI). Transmitters need to be tough to handle these issues.

With MTBF rates exceeding industry benchmarks, our products thrive in high-interference environments like oil platforms and power plants.

Seek IP-rated cases, EMI/RFI protection, and a broad working heat range for lasting dependability.

Exploring ICwalk’s Process Control Board Transmitter Solutions

What Types of Transmitter Boards Does ICwalk Offer?

We at ICwalk provide a full set of process control board transmitters made for different factory demands:

Temperature Transmitter Board

Our H649WD series is built to change inputs from RTDs or thermocouples into straight 4–20mA outputs. H649WD series of isolated temperature transmitters converts the ThermoCouple (TC) or Resistance Temperature Detector (RTD) signals from the field, after digital linearization processing, into a temperature-linear 4-20mA current isolated output. These boards suit heat checking in HVAC systems, production lines, and similar areas.

Pressure Transmitter Board

Our H3051 series pressure transmitters use HART protocol and give top-notch noise resistance. H3051 series intelligent pressure transmitters are specifically designed for high-performance diffused silicon, single-crystal silicon and other bridge-resistance pressure sensors based on the HART protocol. These find wide use in water handling, oil, space, and power fields.

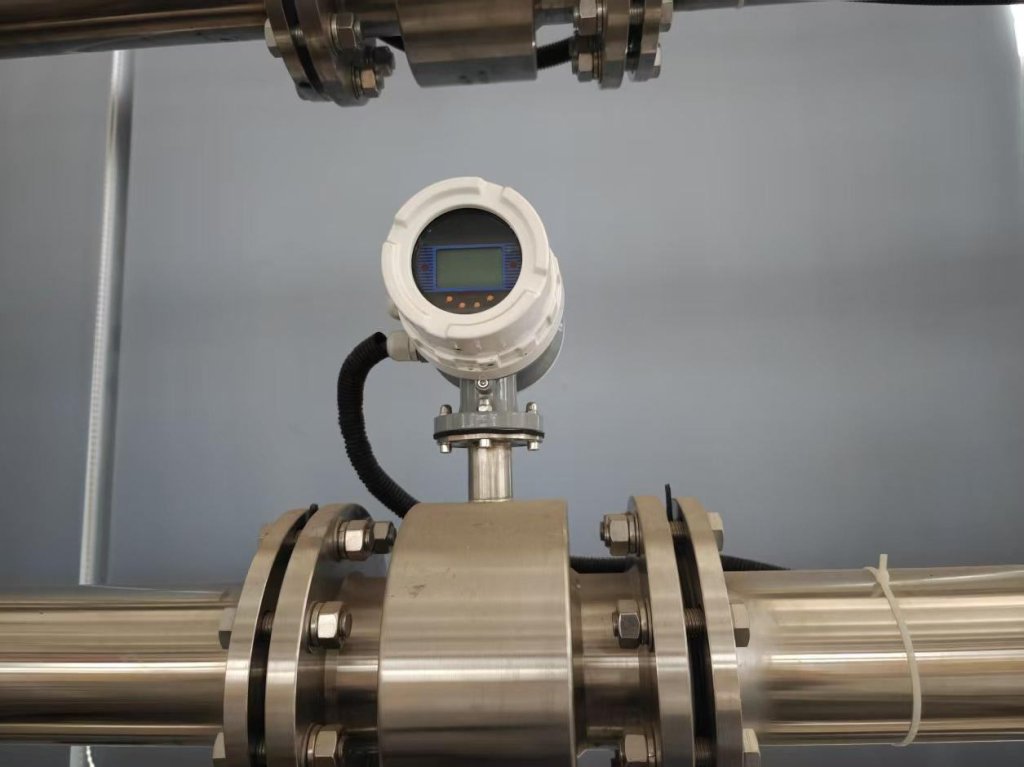

Flow Transmitter Board

We supply options like the H8250FZ metal-tube rotameter board with HART support. The H8250FZ intelligent float transmeter board is specially designed for high-performance intelligent metal rotameter (float) flow transmitters with HART protocol. It fits food handling, chemical adding, and eco-watching tasks.

Level Transmitter Board

Our capacitive level transmitter H509 gives high exactness and strength against rough settings. The H509 capacitive level transmitter serves as the core component of a level gauge. It supports inventory management in silos and tanks used in industries such as chemicals, food processing, and petroleum.

Why Choose ICwalk for Your Process Control Needs?

As a Beijing-based high-tech enterprise founded in 2007, we have over 16 years of experience delivering high-performance instrumentation globally. ICwalk, we are a Beijing-based high-tech enterprise established in 2007, dedicated to revolutionizing industrial automation through precision instrumentation and intelligent process control solutions.

Our transmitter boards are made for steadiness, easy adding, and tailoring. We’ve supplied 200+ custom fixes for 800+ makers, aiding many sensor types (pressure, temperature, level, flow).

We also give personal tech help to ease your setup. For every partnership, we establish an exclusive technical support group. Enjoy responsive, one-on-one service from our expert engineers—ensuring rapid issue resolution and smooth project delivery.

Practical Considerations Before Making a Purchase Decision

How Do You Match the Right Transmitter to Your Application?

Begin by spotting the main process factor you want to watch—heat, force, height, or movement. Then check setting factors like contact with eating chemicals or shakes from machines.

For instance, in eating settings such as waste water plants, ultrasonic flow transmitters work well. They have echo blocking and eating-proof design. Open channel flowmeter is widely used in water plant and sewage treatment plant.

What Maintenance Requirements Should You Expect?

We build our boards with inner check tools like error spot currents (e.g., 3.8mA or 22mA outputs on problems). The current output will be 3.8mA or 22.0mA when detect fault. Setup tools and save features let you fix issues fast.

The manufacturer can back up the original configuration information. When the instrument works abnormally due to illegal adjustment on site by the user can restore the factory settings

We also supply full guides and live aid from our tech teams.

How Can Scalability Influence Long-Term Value?

Think about if your transmitter allows add-on parts or software updates. At ICwalk, our items are made for ongoing growth via flexible bases.

With patented algorithms and steady research, our fixes keep you current with field shifts. They aid your item’s tech growth.

This lowers later swap costs. It also keeps fit with new automation tech.

FAQ

Q: What is the difference between a sensor and a transmitter board?

A: A sensor spots physical factors like heat or force, while a transmitter board turns these sensor reads into standard electric signals usable by control systems.

Q: Can I use one type of transmitter board across multiple applications?

A: While some boards work in many ways, it’s wise to pick a board made just for your process factor—such as ICwalk’s Temperature or Flow Transmitter Boards—for best results.

Q: How do I ensure my transmitter board remains accurate over time?

A: Do regular checks per maker rules and use top parts like those from ICwalk to hold long-term exactness. Our automated production and testing systemsguarantee reliable performance for every board—even in large batches.