How to Assemble a Flowmeter Faster and More Accurately

Why Are Flowmeter Parts Such a Big Deal?

What’s the Deal with Each Flowmeter Piece?

A flowmeter’s a legit precision gadget made of a bunch of key bits, all working together to nail fluid measurements. The main players are the sensor (like a float or rotor), the transmitter board, the housing, the display module, and the output interface.

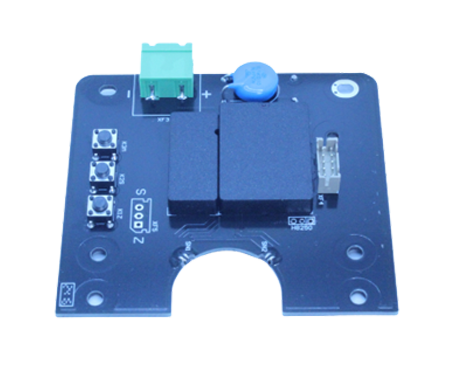

The sensor’s out there catching flow vibes like speed or movement. The transmitter board flips that physical stuff into an electrical signal and gets it ready to roll. For example, in our H8250FZ model, the intelligent flow transmitter board is specially designed for high-performance intelligent metal rotameter (float) flow transmitters with HART protocol. It keeps measurements crazy accurate and steady for all sorts of industrial gigs.

The display module—usually a slick LCD—gives you real-time flow rate and total flow numbers. The output interface (like 4-20mA or HART) chats with external control systems.

How Do These Parts Mess with Assembly Speed and Accuracy?

Each piece’s design straight-up changes how fast and spot-on you can slap a flowmeter together. Pre-calibrated, modular parts cut down on build time.

When boards come with built-in options like alarm settings or total flow reset—like ours do—it skips a bunch of manual setup steps during assembly.

What Tools and Tricks Make Flowmeter Assembly a Breeze?

What Gear Do You Need to Get It Done Fast?

To put a flowmeter together like a pro, techs lean on:

- Precision screwdrivers

- Multimeters for checking electrical stuff

- Calibration tools

- Configuration software that plays nice with HART or MODBUS

- Soldering stations (if you’re doing custom wiring)

Our ICwalk gear is built to vibe with these tools. Comprehensive configuration software and tools support one-stop calibration and commissioning, streamlining your development cycle from design to mass production.

Tricks to Make Assembly Super Accurate

Nailing accuracy starts with handling parts right. Use anti-static mats for circuit boards to keep ‘em safe. Stick to the maker’s torque settings when tightening sensor mounts to avoid wonky alignment.

Another move is setting up transmitter settings before you install. With ICwalk boards, configuration includes engineering units, measured medium, medium density, float density, measurement range, display, alarm values, etc., and the cumulative flow clearing. This cuts out screw-ups from manual tweaks on-site.

Dumb Mistakes to Dodge During Assembly

Common slip-ups include:

- Janking up the transmitter board wiring

- Screwing up sensor alignment

- Skipping calibration after building

- Blowing off diagnostic checks

Steer clear by using checklists and boards with diagnostic outputs. When the instrument fails, it outputs an alarm output current. This helps spot problems early.

How Do You Make the Flow Transmitter Board Fit Like a Glove?

What’s a Flow Transmitter Board and What’s Its Deal?

A flow transmitter board is the brain of the operation, turning sensor signals into standard outputs for control systems. It also handles settings, diagnostics, calibration data, and communication protocols.

Take the H8250FZ intelligent flow transmitter board—it’s a beast in tons of industrial fields, rocking ±0.35% accuracy under standard conditions and killer long-term stability.

Tips for Nailing Flow Transmitter Board Setup

- Get the voltage right: Our boards work with 9V – 32VDC.

- Match the communication protocol: Pick HART or RS485 based on your setup.

- Lock in connections: Use proper plugs like the 2P green plug (2ERJK – 7.62 – 02P).

- Set it up first: Dial in alarm limits, measurement units, and all that jazz.

- Use backup tricks: The manufacturer can back up the original configuration information entering the damping value “5678” can restore the factory settings.

Meet ICwalk: Leveling Up Flowmeters with Dope Components

Who’s ICwalk and What’s Their Deal?

At ICwalk, we’re all about dropping next-level transmitter board solutions for flowmeters across all kinds of industries. Our automated production and testing systems, plus electronic barcode tracking, make sure every board’s a total banger—even in huge batches.

From chemical plants to city water systems, our stuff’s built for performance and easy integration.

Why Go with ICwalk’s Flow Transmitter Board?

ICwalk transmitter boards are trusted by over 800 instrument makers in China because they bring:

- Rock-solid reliability in gnarly environments

- Compatibility with global protocols like HART and PROFIBUS-PA

- Insane accuracy (up to ±0.35%)

- Wide range ratio (1500:1)

- Lightning-fast response speed

Teaming up with ICwalk means you get world-class boards and a crew that’s got your back.

Calibration and Testing After You’re Done Building

Why’s Calibration After Assembly Such a Big Deal?

Even with pre-calibrated parts, calibrating after assembly makes sure everything’s vibing together under real-world conditions. It also catches any weirdness from the build process.

Flow Calibration: 2 – 16 calibration points can be selected on our boards to fine-tune performance across different ranges.

How to Knock Out Basic Calibration Steps Like a Pro

- Power up with the right DC supply (9V – 32V).

- Hook up to configuration software via HART/RS485.

- Plug in known flow values with calibration gear.

- Tweak the output current as needed.

- Go for multi-point calibration if you need it (up to 16 points).

- Save your settings—and back ‘em up with onboard recovery features.

The analog output current can be calibrated, ensuring compatibility with control systems.

FAQ

Q: What’s a flow transmitter board?

A: It’s the electronic brain that turns sensor signals into standard outputs like 4–20mA or digital protocols like HART.

Q: Why pick ICwalk’s flow transmitter boards?

A: ICwalk flow transmitter boards are trusted by over 800 instrument manufacturers in China due to their proven reliability, customization capabilities, protocol compatibility, and rapid technical support.

Q: Can I use ICwalk flow transmitter boards in rough environments?

A: Hell yeah, our board matches global standards, so it’s solid for tough spots like oil & gas or pharma.

Q: How do I reset my ICwalk flow transmitter board if it’s acting up?

A: Just punch in the damping value “5678” to reset to factory settings—it’ll get back to normal in no time.

Q: Do you do tech support for my flow transmitter board?

A: For sure! For every partnership, we set up an exclusive technical support group to fix issues fast.

Related Posts

-

Why Over 70% China’s Instrument Manufacturers Chose ICwalk as Their Supplier of Choice

September 25,2025

-

Why Is Calibration Crucial for Accurate Level Measurement with Transmitters?

August 28,2025

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

What Role Does the Circuit Board Play in Signal Processing for Transmitters?

September 11,2025