How the Board Inside Your Smart Process Control Board Transmitter Boosts Your System Uptime

Understanding the Role of a Smart Process Control Board Transmitter

What Is a Process Control Board Transmitter and Why Does It Matter?

A process control board transmitter acts as the key bridge between field sensors and control systems. Its main job is to take raw readings from sensors—like temperature, pressure, or flow—and turn them into standard electrical signals. PLCs or DCSs can easily understand these signals. Common formats include 4–20 mA loops or digital protocols such as HART and Modbus.

This conversion is essential for live monitoring and automatic control in factories. It helps keep processes stable, safe, and efficient. The transmitter’s output lets operators adjust equipment, watch key variables, and meet regulatory requirements.

Smart transmitters go further. They contain built-in microcontrollers. These add useful features: diagnostics, remote calibration, and digital signal processing. That is why smart process control board transmitters have become vital in today’s automation setups, especially where reliability and uptime really count.

How Do Smart Features Improve Signal Accuracy and Reliability?

Smart process control board transmitters rely on internal microprocessors to protect data quality. The processors remove noise from sensor signals. They also correct for temperature or humidity changes automatically. As a result, accuracy stays steady even when conditions vary.

Automatic self-calibration is another major advantage. The transmitter adjusts its own reference points over time. This reduces the need for manual checks and keeps performance stable for years. For instance, smart temperature transmitters often use known reference values to stay precise in heat-sensitive processes.

Real-time diagnostics are built into the board as well. They watch sensor health constantly. Problems such as drift, broken wiring, or sensor wear are caught early. Alerts appear before a small issue becomes a shutdown.

Exploring the Functions of Different Types of Transmitter Boards

What Are the Key Differences Between Pressure, Temperature, Flow, and Level Transmitter Boards?

Pressure Transmitter Board

A pressure transmitter board measures the force that gases or liquids apply inside pipes or vessels. It usually works with strain-gauge or piezoelectric sensors. These detect pressure changes and convert them into electrical signals. Pressure transmitter is used to measure the gas, steam’s level, density, and press. Then transform it into 4-20mA DC signal connecting to PC, control instrument etc.

The output helps control pumps and valves or trigger alarms instantly. Safety and efficiency depend on it.

Temperature Transmitter Board

Temperature transmitter boards take signals from thermocouples or RTDs and convert them into standard formats. H3051WD Intelligent Temperature Transmitters are specifically designed for high-performance HART protocol temperature measurement applications. These transmitters are compatible with a range of standard thermoresistors, including PT50, PT100, PT500, and PT1000, as well as a variety of thermocouples such as types E, J, B, K, N, R, S, and T.

Accurate thermal control is critical in chemical plants or food production lines. These boards deliver it.

Flow Transmitter Board

Flow transmitter boards measure how much liquid or gas moves through a pipe—either by volume or mass. They accept inputs from differential-pressure devices, electromagnetic meters, and similar technologies. Electromagnetic Flow Transmitter Precise Measurement, Excellent Performance boards enable accurate dosing, mixing, and batching in production environments where flow rate control impacts product quality and safety.

Level Transmitter Board

Level transmitter boards track how full a tank or vessel is. They use ultrasonic, radar, or capacitive sensors. The data supports inventory management and prevents overflows in storage or wastewater plants.

How Do These Boards Work Together in an Integrated System?

In a complete control system, several transmitter boards send their data to one central controller—usually a PLC or DCS. All the information comes together there for an overall view.

Feedback loops make automatic corrections in real time. For example, when a level transmitter sees a tank almost full, the system can shut the inlet valve and notify the operator at the same time. This closed-loop design keeps everything running smoothly with almost no manual input.

Enhancing System Uptime with Smart Monitoring Capabilities

How Does Real-Time Diagnostics Reduce Downtime?

Real-time diagnostics are a major reason smart systems stay online longer. The transmitter boards watch themselves and the sensors continuously. The software has the function of intelligent self-inspection, further ensuring high reliability on-site.

If a cable breaks or a sensor starts drifting, an alarm appears immediately. Maintenance teams get warned early. Repairs can wait for a scheduled stop instead of causing an emergency shutdown.

What Role Does Predictive Maintenance Play in Uptime Optimization?

Predictive maintenance uses the data that smart process control board transmitters collect over time. It predicts when parts will wear out. The EEPROM has an enhanced anti-interference design and complete data backup and recovery functions, thoroughly realizing maintenance-free operation on site.

Technicians service equipment based on real condition, not a fixed calendar. Machines run longer, and unnecessary replacements drop.

Can Remote Access Improve Operational Efficiency?

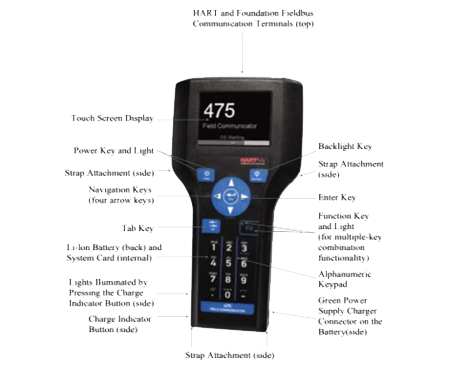

Yes—most smart transmitters allow remote connection through HART, Modbus, or similar protocols. Technicians can adjust settings, update firmware, or fix problems from anywhere. HART-Tool configuration software can flexibly and conveniently configure the measurement range of sensors and the range of transmitters.

This is extremely helpful for hard-to-reach locations like offshore rigs or remote water plants.

How to Choose the Right Process Control Board for Your Application?

What Specifications Should You Consider Before Selecting a Transmitter Board?

Several technical details matter when you pick a process control board transmitter:

- Input signal type: Make sure it matches your sensor (voltage from thermocouples, resistance from RTDs, etc.).

- Output format: Decide if you need analog 4–20 mA or digital HART/Modbus signals.

- Environmental resistance: Check temperature range, humidity rating, and explosion-proof options.

Practical features like rotatable displays or remote-mount housings also make installation and reading easier.

Why Is Compatibility with Existing Systems Important?

Good compatibility saves time and money during installation. If protocols don’t match, you may need extra converters or even a major redesign.

Standard 4–20 mA outputs work with almost any older system. New boards can drop in without big changes.

Spotlight on ICwalk’s Transmitter Circuit Boards

Modular Design Across Multiple Applications

We supply dedicated boards for pressure, temperature, flow, and level measurement—allowing easy customization across industries such as oil & gas, water treatment, and manufacturing.

Customers can expand their systems without changing suppliers or redesigning everything.

What Makes ICwalk’s Products Stand Out in Industrial Applications?

Precision Engineering for Critical Measurements

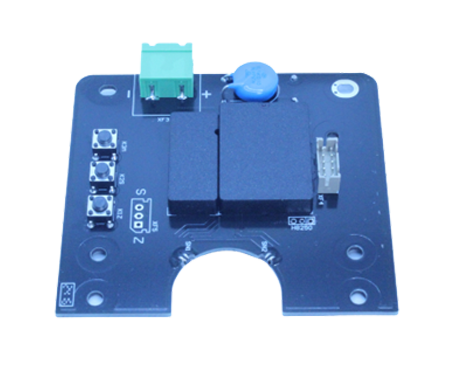

ICwalk pressure transmitter circuit boards are built for high-resolution, stable performance even under changing conditions. H3051 series intelligent pressure transmitters are specifically designed for high-performance diffused silicon, single-crystal silicon and other bridge-resistance pressure sensors based on the HART protocol.

Industries such as aerospace, petrochemical, and water management trust our boards because precise pressure data is essential there.

Built-In Diagnostic Intelligence

ICwalk integrates smart diagnostics that monitor board health and sensor integrity in real time—supporting predictive maintenance strategies.

Operators see problems coming and fix them before production stops. Uptime rises and maintenance costs fall.

Seamless Integration with Control Systems

Our boards support standard 4–20 mA loops and HART protocol right out of the box. Designed for compatibility with standard industrial protocols such as 4–20 mA output and HART communication.

They connect directly to your existing PLC or DCS with no extra hardware.

FAQ

Q: What is the function of a process control board transmitter in an industrial system?

A: A process control board transmitter converts raw sensor data into standardized signals that can be interpreted by control systems like PLCs or DCSs. This enables real-time monitoring and automated adjustments to maintain optimal operating conditions.

Q: How does a smart transmitter differ from a traditional one?

A: Smart transmitters include embedded microcontrollers that allow features like self-diagnostics, remote calibration, digital communication (e.g., HART), and enhanced accuracy through temperature compensation.

Q: Can I use the same transmitter board for different types of sensors (pressure vs temperature)?

A: No—each type of transmitter board is specifically designed to handle particular sensor inputs (e.g., strain gauge for pressure vs RTD/thermocouple for temperature). However, modular systems like those offered by ICwalk provide compatible boards tailored to each application type while maintaining unified integration protocols across your system architecture.

Related Posts

-

Top 5 Field Communicator Issues and How to Fix Them

November 20,2025

-

What Is a Field Communicator and How It Improves Communication Flow

August 14,2025

-

The Ultimate DIY Guide: Step-by-Step Assembly of a Precision Level Meter

October 23,2025