How Do You Select the Right Flow Transmitter Board for Your Application Needs?

What is the Role of a Flow Transmitter Circuit Module?

What Is a Flow Transmitter Circuit Module and How Does It Work?

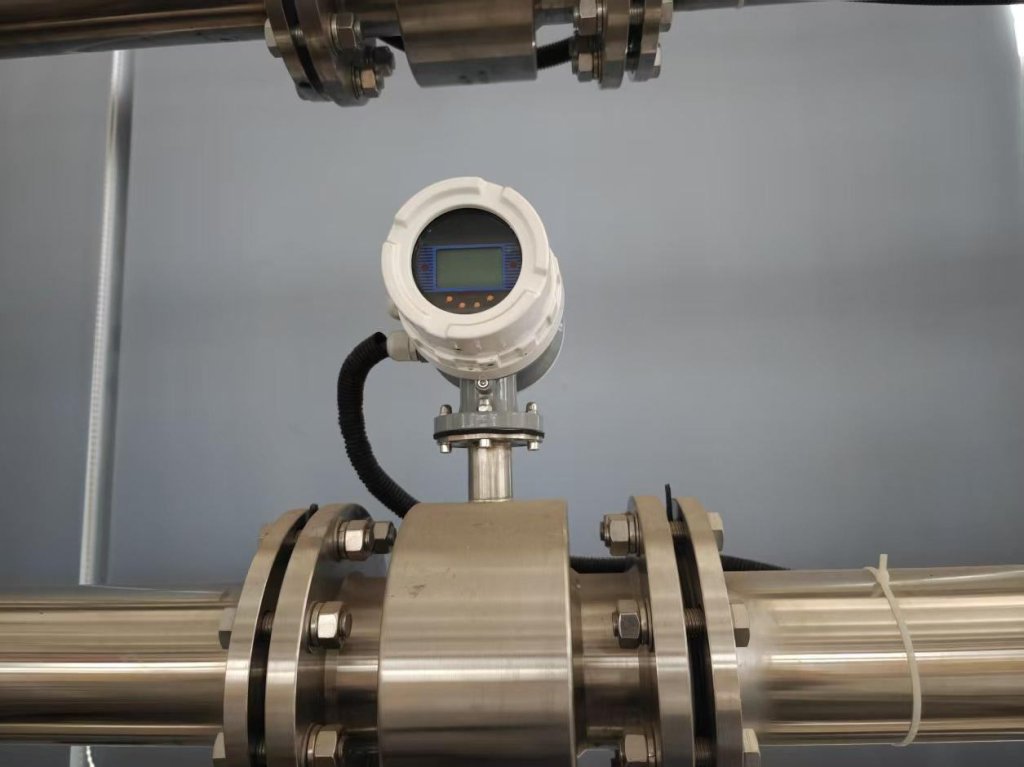

A flow transmitter circuit module serves as a key part in fluid monitoring setups. It works by turning flow information—like speed or amount—into an electric signal. This signal can be detected and handled by control setups. Usually, these modules combine flow sensors, boosters, and signal adjustment parts. They make sure precise and steady signals reach many industrial uses.

In real-world use, a flow transmitter gets data from a flow sensor. Then, it handles the basic signal with built-in electronics. After that, it sends out a standard signal, such as 4–20 mA or a digital method like HART. This setup design allows easy fitting into programmable logic controllers (PLCs) and building automation systems.

Why Is Accurate Flow Measurement Important in Your System?

Precise flow measurement matters a lot for keeping system output, safety, and rule-following in check. In tasks like chemical adding or water cleaning, small mistakes can cause waste of goods, nature risks, or gear harm.

For instance, submersible level transmitters play a crucial role in water management, oil and gas, and chemical processing. They help keep operations safe and smooth. Flow transmitter modules need the same kind of exactness. This supports key jobs like finding leaks, improving processes, and meeting report rules.

Key Factors to Consider When Choosing a Flow Transmitter Circuit Module

What Types of Fluids Will You Be Measuring?

The main thing to think about when picking a flow transmitter circuit module is how well it fits with the fluid. Various modules suit certain kinds of substances—some handle gases, while others deal with liquids. Traits such as thickness, heat level, and chemical strength need to line up with the module’s sensor build and materials.

What Is the Required Accuracy and Measurement Range?

Different uses have different limits on mistakes. Some tasks need ±1% exactness, but others—like careful adding—call for even closer limits. Units like the ICwalk E4000 series give general measurement exactness of ±0.3%R to ±1.0%R. This depends on the flow speed span and pipe size. As a result, they fit well for tasks that demand high exactness.

Make sure the chosen module handles your planned flow amounts. It should not lose detail or quick reply time.

How Will the Module Interface With Your System?

The type of signal output decides how smoothly the module links with current setups. Basic choices like 4–20 mA see wide use in factory automation. This is because they stand up well to interference over far stretches.

ICwalk’s E4000 series supports multiple output modes including 4–20 mA, HART, RS485/MODBUS RTU. Thus, they provide options for old and new control setups.

What Are the Environmental Conditions of Operation?

Toughness against surroundings is a must in rough factory spots. Things like wetness, heat highs and lows, dirt, and chemical contact can harm module steadiness. Modules need proper IP levels. Also, they should be heat-rated to fit the place’s setup.

ICwalk’s E4000 modules operate within a wide temperature range of -20°C to +70°C. So, they work well in tough spots, including outside setups.

Electrical and Signal Specifications You Should Evaluate

What Power Supply Requirements Must Be Met?

Steady power feed is needed for even module work. ICwalk’s E4000 supports both AC (85–305V) and DC (18–30V) power supplies. This gives fitting ease in mixed setups.

Modules that take broad voltage spans cut down on fitting problems. They also make setup simpler across many use kinds.

How Does Signal Conditioning Affect Performance?

Signal adjustment covers clearing out interference and boosting faint sensor results. It plays a big part when sending signals far or in spots with electric buzz.

Signal filtering improves accuracy by reducing noise and interference. Meanwhile, built-in boosting makes sure sensor signals can be seen by controllers and show systems.

Common Applications of Flow Transmitter Circuit Modules Across Industries

Where Are These Modules Most Commonly Used?

Industrial Automation Systems

Flow transmitter circuit modules find broad use in making plants. They watch fluid movement, like coolant flow or oil for lube cycles. These modules give instant input to process guides. This leads to exact automation handling.

Building Management Systems (BMS) & HVAC Control

Modules help with smart energy saving by following chilled water or air movement. In heating, ventilation, and air-conditioning systems, it can measure the flow of refrigerants, water in heating and cooling loops. All this ensures better weather handling.

Water Treatment and Distribution Networks

Modules matter greatly in controlling in and out flow for water stores and cleaning plants. Monitoring water levels in tanks, reservoirs, and pipelines ensures efficient water distribution and storage. Flow transmitters handle a similar vital job here.

Oil & Gas Monitoring Systems

Flow transmitter boards aid in safe fuel moving through pipes. They do this by giving steady watch over amount speeds. Right readings stop too much pressure. They also spot leaks fast.

Introducing ICwalk’s Flow Transmitter Board Solutions

What Makes ICwalk‘s Flow Transmitter Board a Reliable Choice?

At ICwalk, we supply carefully built flow transmitter circuit modules. They suit many factory needs. Our products match global standards, ensuring smooth integration and easy export. Plus, they work with HART and PROFIBUS-PA methods.

We’ve delivered 200+ customized solutions for 800+ manufacturers. This proves our fit across fluid kinds and setup needs.

How Can ICwalk Products Enhance Your System Performance?

Features of ICwalk Flow Transmitter Boards:

Our E4000 electromagnetic flow transmitters provide changeable output choices. These include 4–20 mA current output and digital talk methods like HART and MODBUS. They are equipped with advanced anti-interference technology. Also, they have data backup and recovery functions to keep measurement wholeness.

Benefits of Choosing ICwalk:

- High accuracy ensures dependable readings across varied applications

- Durable construction supports long-term reliability in industrial settings

- Automated testing systems guarantee consistent quality even in large batches

FAQ

Q: Why does signal type matter when selecting a flow transmitter module?

A: The signal type determines how easily your system can interpret data from the module; analog signals like 4–20 mA are common in industrial systems due to their noise resistance over long distances.

Q: How does temperature affect flow transmitter module performance?

A: Extreme temperatures can alter sensor accuracy or damage internal electronics; selecting a temperature-rated board ensures reliable operation under specific conditions.

Q: Can I install these flow transmitter modules outdoors?

A: Yes—if the module has an appropriate IP rating (e.g., IP65 or higher) to protect against dust and moisture intrusion commonly found in outdoor environments.

Q: What is the difference between a flow transmitter and a flow sensor?

A: A flow sensor detects fluid movement but may not provide standardized output signals. A flow transmitter includes signal conditioning components to convert raw data into readable electrical signals like 4–20 mA or voltage outputs.

Q: Can I use one flow transmitter board for different types of fluids?

A: It depends on the design specifications of the board. Some boards are fluid-specific due to material compatibility or sensor calibration, while others are built to handle multiple fluid types with configurable settings.

Q: How do I troubleshoot inaccurate readings from my flow transmitter circuit module?

A: Look for blockages in the fluid route. Check wiring links. Make sure power feed levels are right. Also, verify that surroundings fit the set limits for the module’s work.

ICwalk gives top support via our focused 1-on-1 tech help group. They guide you in setup, tuning, or fixing steps.

Ready to integrate a reliable, high-performance flow transmitter circuit module into your system? Contact us at ICwalk—we’re here to help accelerate your success.