How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

What Are Temperature Transmitter Boards and Their Uses?

What Does a Temperature Transmitter Board Do?

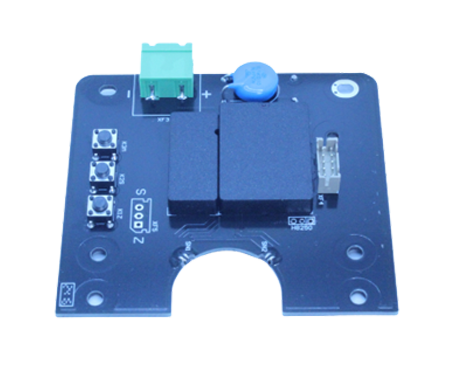

Temperature transmitter boards are key parts in modern industrial and environmental tracking systems. Their chief role is to change temperature readings from sensors, like thermocouples (TC) or Resistance Temperature Detectors (RTD), into a steady signal. This is usually a 4-20mA current output. The signal matches the measured temperature. It guarantees accurate data transfer over long distances.

For example, ICwalk’s H648WD series of isolated temperature transmitters linearize signals from different RTDs and thermocouples. They turn these into a linear 4-20mA output. These units also have features like cold junction compensation for thermocouples. They handle millivolt and resistance signal measurements.

How Are Temperature Transmitter Boards Used in Various Fields?

Temperature transmitter boards are applied in many fields due to their flexibility and precision. In manufacturing, they watch over key processes. They keep machinery within safe temperature ranges. The oil and gas field uses these boards for pipeline tracking and refining tasks. In pharmaceuticals, they ensure strict environmental conditions for drug production.

ICwalk’s products, such as the H3051WD Intelligent Temperature Transmitter, are made for high-performance needs. They work with various standard thermoresistors and thermocouples. Their tough build ensures dependability in harsh settings.

Key Traits of Advanced Temperature Transmitter Circuit Modules

Advanced temperature transmitter circuit modules offer several vital traits that improve their performance:

- High Precision: ICwalk’s H648WDgives an output accuracy of 0.1%. This ensures exact readings.

- Wide Compatibility: These modules support many sensor types, including Pt100, Pt500, Pt1000 RTDsand type K, J thermocouples.

- Electrical Isolation: They offer isolation voltages up to DC1000V. This shields against electrical noise.

- Durability: They work in temperatures from -40°C to +85°C. This suits them for extreme conditions.

- HART Communication Protocol: This enables smooth integration with modern industrial systems.

How Are New Technologies Shaping Temperature Transmitter Boards?

What Role Does Miniaturization Play in Modern Modules?

Miniaturization has changed temperature transmitter board design. It creates small yet strong devices. Compact modules save space in installations. They keep high performance. For instance, ICwalk’s H649WD series has a 44mm diameter. It still supports varied sensor inputs and advanced features like digital linearization. This meets the need for efficient, space-saving solutions in industries.

The Role of Smart Features in Temperature Transmitter Boards

Smart features have boosted temperature transmitter board capabilities. Modern units now allow remote control via handheld devices or PC software. ICwalk’s HART-CONFIG software lets users set up, fix, maintain and adjust transmitters easily. Advanced models also have real-time data updates. They include adjustable damping settings to improve performance in changing conditions.

How Does ICwalk Advance This Technology?

At ICwalk, we focus on pushing temperature transmitter technology forward. Our products combine precise engineering with advanced features. They meet growing industry demands. The H3051WD module shows this focus. It offers high-voltage isolation, military-grade anti-interference features and customizable settings for better user control. We improve our designs based on user feedback and technological advances. Our aim is to set new standards in performance and dependability.

Market Impact of Evolving Temperature Transmitter Boards

How Do New Features Affect Market Demand for Modules?

New features in temperature transmitter circuit modules have boosted market demand. They tackle key issues like precision, compatibility and durability. Industries prefer advanced solutions. These blend easily with existing systems and offer better features. For example, the H648WD series supports multiple sensor types. This makes it a flexible choice across fields. As industries adopt automation and smart technologies, demand for advanced boards grows.

The Role of ICwalk’s Products in Meeting Market Needs

ICwalk’s products are built to meet varied market needs effectively. We offer affordable options like the D148D model. We also provide high-performance solutions like the H3051WD with an LCD screen. Our range suits different application scenarios. By blending quality with affordability, we deliver value-driven solutions. These improve operational efficiency.

Emerging Trends and Their Economic Impact

New trends like IoT integration and predictive maintenance are reshaping the industry. These allow real-time tracking. They enable proactive problem-solving. This cuts downtime costs greatly. Features like rotatable LCD displays on models like H3051WD improve usability. They appeal to operators seeking easy-to-use interfaces. As these trends spread globally, ICwalk is ready to seize opportunities. We deliver innovative products that match market needs.

By using cutting-edge technology and user-focused design, ICwalk leads in advancing temperature transmitter board technology worldwide.

Benefits of Using ICwalk’s Temperature Transmitter Boards

Why Pick ICwalk for Quality Circuit Modules?

ICwalk is a top provider of advanced temperature transmitter circuit modules. We offer solutions for diverse industry needs globally. Our dedication to innovation and precise engineering ensures excellent performance and reliability. Located at Room 701, Building 1, No. 1 Shangdi East Road, Haidian District, Beijing, we focus on creating cutting-edge temperature transmitter boards for various uses.

Reliability and Performance of ICwalk Products

ICwalk’s temperature transmitter boards set industry standards for reliability and performance. Our H648WD series linearizes signals from thermocouples (TC) or Resistance Temperature Detectors (RTD). It converts them into a linear 4-20mA current output tied to temperature. This series supports a wide range of RTDs, including Pt50, Pt100, Pt500, Pt1000 and thermocouples like types E, J, K, N, R, S and T. The units include internal cold junction compensation. This ensures accurate readings in changing environments.

The H3051WD Intelligent Temperature Transmitter boosts reliability. It features high-voltage isolation up to DC1000V. This suits it for tough industrial settings. Its anti-interference features protect against over-voltage, surge, electrostatic discharge and lightning issues. The module also offers adjustable settings for zero trim, sensor trim, damping and more. These allow precise customization for specific uses.

Cost Efficiency and Customization Options from ICwalk

ICwalk values cost efficiency without sacrificing quality. Our product range includes budget-friendly options like the D148D model. We also offer high-performance solutions like the H3051WD with an LCD screen. The H648WD has a compact 44mm diameter. It keeps strong functionality, ideal for space-limited setups.

Customization is a major benefit. For RTD connections in the H648WD, users can choose two-wire, three-wire, or four-wire setups based on their needs. Thermocouple connections use built-in cold junction compensation. This can be turned on or off as needed.

Our products support remote management via HART-CONFIG software. Users can set up and adjust transmitters easily using handheld devices or PC software. This flexibility boosts efficiency. It also lowers maintenance costs over time.

FAQ

Q: How Do Innovations Improve Measurement Precision?

A: Innovations in temperature transmitter boards have greatly improved precision. They use advanced technologies like digital linearization and cold junction compensation. For example, the H649WD converts TC or RTD signals into a temperature-linear 4-20mA output. It achieves an accuracy rate of up to 0.2%. These features ensure exact readings in tough environments.

Models like the H3051WD offer stability of ±0.2% per year. This improves long-term reliability. Real-time data updates (2 Hz) and adjustable damping settings let users tailor performance to specific needs.

Q: Why Is Compatibility Important in Modern Modules?

A: Compatibility is a foundation of modern temperature transmitter boards. ICwalk’s products support many sensor types. These include RTDs like Pt100 and Pt1000 and thermocouples like types K and J. This flexibility suits a wide range of fields.

The HART communication protocol in models like the H648WD allows easy integration with existing industrial systems. This ensures our products fit into new setups or upgrades of older systems.

Q: How Are Smart Features Changing Temperature Transmitter Boards?

A: Smart features are transforming temperature transmitter boards. They improve user convenience and efficiency. ICwalk’s HART-CONFIG software simplifies setup and troubleshooting. It uses an easy-to-follow menu system. Field adjustment functions let users change settings like range or transfer functions on-site.

Advanced models include user-friendly interfaces like rotatable LCD displays. These offer clear visibility in low-light conditions. These innovations improve usability. They also cut downtime during maintenance.

By pushing technology forward, ICwalk delivers state-of-the-art solutions. We meet growing market demands.

Related Posts

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

How Does Technology Influence the Evolution of Modern Flow Transmitter Boards?

June 26,2025

-

What Makes the Flow Transmitter Board Crucial for Precise Data Transmission?

July 17,2025

-

How Can TT Temperature Transmitters Improve Process Control in Heat Treatments?

May 29,2025

-

How to Evaluate the Reliability of a Pressure Transmitter Board Under Stress?

July 03,2025