Why Is Calibration Crucial for Accurate Level Measurement with Transmitters?

What Is Level Measurement and Why Does Accuracy Matter?

Understanding the Basics of Level Measurement

Level measurement is all about figuring out how much liquid or solid stuff is in a tank or container. It’s a big deal for industries like chemical plants, oil refineries, water treatment, and food factories. Nailing it keeps everything running smooth, stops spills, keeps quality high, and uses materials smart.

How Do Transmitters Measure Liquid Levels?

Level transmitters are sensors that turn level info into an electrical signal control systems can read. They use cool tech like ultrasonic waves, capacitance, magnetostrictive sensing, or hydrostatic pressure to check fluid levels. Take the H509 capacitive level transmitter—it’s the heart of a level gauge. It’s a tool for building gauges that measure how high liquids or solids are.

What Are the Consequences of Inaccurate Level Readings?

Screwy readings can cause major headaches. Overfilling tanks can lead to spills and eco messes. Underfilling might throw off production plans. In places like pharma or food factories, tiny mistakes can wreck product quality or break rules. Lousy measurements also mess with inventory tracking and can cost cash from wasted stuff or downtime.

Why Is Calibration Essential for Level Transmitter Boards?

What Role Does Calibration Play in Ensuring Accuracy?

Calibration makes sure the transmitter’s output lines up with a known standard to keep readings dead-on. Without it, even badass transmitters can go off track ‘cause of old parts or environmental shifts. The H509 rocks a capacitive setup with a range of 50PF to 5000PF and a resolution of 0.002PF. That kinda precision needs regular checkups to stay tight.

How Often Should a Level Transmitter Be Calibrated?

Depends on the vibe, maker’s tips, and industry rules. Usually, once a year’s solid for normal setups. In rough spots—like places with harsh chemicals or crazy heat—you might need to calibrate more often.

What Factors Can Affect Calibration Over Time?

A bunch of stuff can mess with calibration:

- Temp swings

- Electrical noise

- Mechanical stress

- Sensor wear

- Corrosive gunk

These can make sensors drift from their original setup, so recalibration’s key to keeping things legit.

How Does ICwalk Contribute to Reliable Level Measurement?

Who Is ICwalk and What Do They Offer?

At ICwalk, we’re all about whipping up dope electronics for tricky automation gigs. ICwalk Technology Co., Ltd., based in Beijing’s Haidian District, pumps out a ton of transmitter boards for temp, pressure, flow, and level measurement.

Overview of ICwalk’s Expertise in Industrial Electronics

We’re pros at building tough, high-performing modules that hit strict industry standards for stuff like petrochemical plants, water treatment, and pharma production.

Introduction to ICwalk’s Level Transmitter Board Solutions

Our lineup’s got ultrasonic level transmitter boards like the H760 series and capacitance-based ones. These boards are made for spot-on measurements and slide right into existing systems.

How Do ICwalk’s Products Support Accurate Calibration?

Built-In Features That Enhance Precision

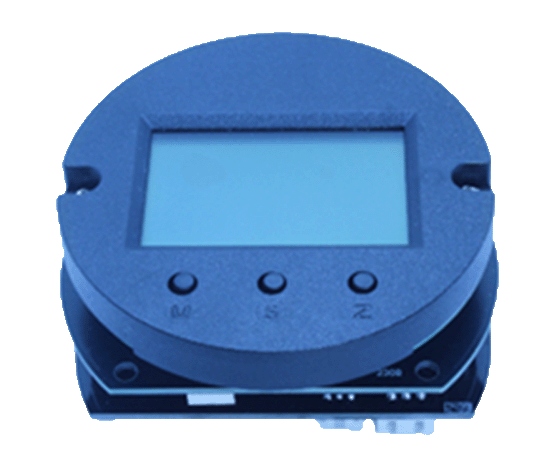

It’s got a slick three-button field calibration feature (works with two-button mode and reed switches too) for stuff like span, zeroing, damping, and data recovery. This lets you tweak things quick without ripping gear apart.

Rocking an emerald green backlit multifunctional LCD display that shows up to four variables at once and spins 360 degrees, our gear makes monitoring a total breeze.

Compatibility and Ease of Integration

We build our level transmitter boards for plug-and-play vibes with all kinds of industrial protocols and control systems. This cuts setup time while keeping performance steady across the board.

What Are the Common Challenges in Calibrating a Level Transmitter Board?

How to Identify Calibration Drift or Sensor Deviation?

Keep an eye out for weird signs like readings that don’t match manual checks or random alarms during normal use. If output numbers don’t jive with actual fluid levels when things are chill, that’s a clue you’ve got drift.

What Tools Are Needed for Proper Calibration?

A standard calibration kit needs:

- Reference-level measuring gear

- Signal simulators

- Multimeters

- Maker-specific software (if you need it)

These help techs dial in exact input values while tweaking the transmitter’s output.

Can Environmental Conditions Impact Calibration Accuracy?

Hell yeah. High humidity can screw with capacitive sensors. Crazy temps might mess with electronics. Dust piling up on sensor surfaces can throw readings off. All this means you gotta recalibrate regularly, even if nothing’s busted.

When and How Should You Perform Recalibration?

Signs That Your System Needs Recalibration

Look out for:

- Sudden spikes or drops in readings

- Gaps between digital outputs and physical checks

- Alarms popping off for no reason

- Weird trends in SCADA systems

Step-by-Step Guide to Performing a Standard Recalibration

Preparing the System for Calibration

Shut down processes safe before yanking any parts. Make sure tanks are empty or filled to known levels for solid comparisons.

Executing Zero and Span Adjustments

Use the interface buttons—or software if you got it—to set zero (empty tank) and span (full tank) points based on real levels. Three buttons cover everything, making it a cinch on our gear.

Verifying and Documenting Results

After tweaking:

- Match new readings against manual checks.

- Jot down results for audits.

- Run tests again under different vibes if needed.

How Does ICwalk Ensure Long-Term Performance in Their Transmitter Boards?

Quality Control Measures by ICwalk

We run hardcore tests at every step—from grabbing components to final assembly—to make sure each board’s up to our high standards.

The modular design keeps things reliable, consistent, and stable for the long haul. All units get factory-calibrated before shipping, so they’re ready to roll right out the gate.

Durability and Signal Stability in ICwalk Boards

With an isolation voltage up to 1000VDC between the sensor and main circuit, our gear blocks electrical noise common in industrial spots. This keeps signals rock-steady even in gnarly conditions.

FAQ

Q: What is the difference between calibration and configuration in level measurement systems?

A: Calibration tweaks the device’s output to match known standards for accuracy. Configuration sets stuff like units or alarm triggers but doesn’t mess with measurement accuracy directly.

Q: How can I tell if my level transmitter board is out of calibration?

A: Look for readings that don’t line up with physical checks or past trends. Sudden shifts without process changes usually mean drift and call for recalibration.

Q: Are ICwalk level transmitter boards suitable for harsh industrial environments?

A: You bet. The H509’s got full isolation up to 1000VDC and long-term stability, making it killer for rough spots like chemical plants or outdoor setups.