What Role Do Level Transmitter Boards Play in Process Automation?

Understanding Level Transmitter Boards

What Is a Level Transmitter Board and How Does It Work?

A level transmitter board is a vital electronic part in industrial automation. It detects, processes and sends signals showing the level of liquids or solids in a tank or vessel. The board links the sensor to control systems like PLCs (Programmable Logic Controllers). It turns raw sensor data into standard electrical signals.

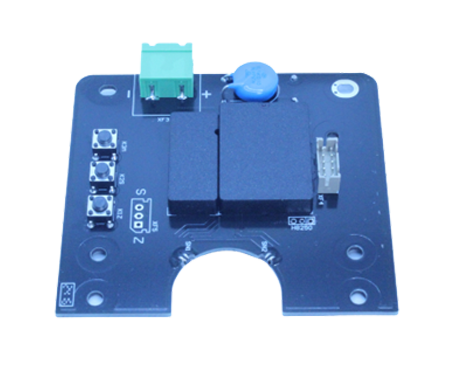

For instance, the H509 capacitive level transmitter is the main part of a level gauge. It measures the height of liquids or solids. These boards ensure monitoring systems get accurate, real-time data about material levels.

How Do Level Transmitter Boards Ensure Accurate Measurements?

Level transmitter boards improve accuracy with advanced signal processing. They use Direct Digital Synthesis (DDS) technology for precise data conversion. This ensures exact readings from sensor inputs. Isolation circuits also shield against noise and interference. This keeps readings reliable in tough industrial settings.

Why Signal Conversion and Communication Matter in Level Monitoring

Sensors often produce signals that control systems can’t directly use. Level transmitter boards handle this by converting analog signals to digital ones. They also condition the signals for clarity. Communication interfaces like 4-20mA outputs or digital protocols connect smoothly to SCADA or PLC systems. This allows centralized monitoring and control.

Applications of Level Transmitter Boards in Industrial Automation

Where Are Level Transmitter Boards Used?

Level transmitter boards are versatile and reliable. They are common in industries like petroleum, chemical engineering, food, pharmaceuticals, water treatment and natural gas. These sectors need precise level measurements for efficient processes and safety.

How Do They Support Continuous Process Control?

In automation, constant feedback is key to maintaining ideal conditions. Level transmitter boards provide real-time data. This lets control systems adjust pumps, valves or alarms as needed. It ensures steady product quality, cuts waste and boosts efficiency.

Why Are They Crucial for Managing Liquids and Solids?

Accurate level detection prevents issues like overflows or shortages. This is vital for managing oil in refineries or grains in silos. Level transmitter boards deliver precise measurements despite changes in pressure or temperature. They help keep storage and processing safe.

Key Features and Technologies of Level Transmitter Boards

What Components Make a High-Performance Board?

Signal Conditioning Circuits

These circuits remove noise from sensor inputs. They also boost weak signals for clear processing.

Analog-to-Digital Conversion Units

These units change analog sensor signals into digital formats. Microcontrollers or PLCs can then read them with little delay.

Output Interface Modules

These modules allow communication with external devices. They use standard protocols like 4-20mA current loops or RS485 Modbus.

How Does ICwalk Innovate in Level Transmitter Board Design?

Compact and Modular Design by ICwalk

ICwalk’s boards are small, fitting tight spaces. Their modular setup adapts to various uses.

Focus on Stability and Accuracy

The modular design ensures reliability and consistency. It also supports long-term stability. ICwalk’s boards include a three-button calibration feature. This works with two-button mode and reed switches. It supports functions like span, zeroing, damping and data recovery.

Benefits of Using Level Transmitter Boards in Automation

How Do They Boost Efficiency and Cut Downtime?

Level transmitter boards give accurate, real-time data with low maintenance needs. They have full data backup and recovery. This helps operators restore settings quickly after issues. It reduces unexpected downtimes greatly.

How Do They Improve Safety and Compliance?

Many industries face strict rules on hazardous material storage. Level transmitter boards ensure constant monitoring. They trigger alarms when levels exceed limits, helping meet regulations.

Why Are ICwalk’s Boards Cost-Effective?

ICwalk’s products are durable and need little maintenance. They have full isolation with up to 1000VDC between the sensor and main circuit. This protects against electrical surges, lowering lifecycle costs.

Choosing the Right Level Transmitter Board

What Should You Consider When Selecting a Board?

Measurement Range and Resolution

Pick a board that fits your application’s sensitivity needs. The H509 uses a capacitive structure. It has a range of 50PF to 5000PF and a resolution of 0.002PF.

Environmental Conditions

Choose boards suited for high temperatures or corrosive settings. Ruggedized models handle tough conditions.

Integration with Control Systems

Ensure the board’s output matches your infrastructure. ICwalk’s boards support standard outputs for easy integration.

Why Choose ICwalk for Automation Components?

ICwalk offers various boards, like Ultrasonic, Magnetostrictive and Capacitance Level Transmitter Boards. They are built for industrial performance at fair prices. ICwalk’s focus on innovation keeps solutions future-ready.

Real-World Integration: ICwalk’s Products Simplify Monitoring

Which ICwalk Products Work Well with Industrial Networks?

The ICwalk H760 Ultrasonic Level Transmitter Board is designed for easy use in automated systems. It supports standard communication protocols.

Overview of ICwalk’s Standard Boards

ICwalk offers series for different sensing needs. Ultrasonic boards work for non-contact uses. Magnetostrictive Level Transmitter Boards provide high accuracy. Capacitance-based models like H509 suit conductive and non-conductive materials.

Customization Options by ICwalk

ICwalk’s team supports custom designs for specific industries. From housing materials to interface protocols, we tailor solutions for sectors like oil and gas or food processing.

How Does ICwalk Ensure Quality and Support?

All products undergo strict testing before shipping. Our customer service team offers pre-sales advice and post-installation support. Contact us at Room 701, Building 1, No. 1 Shangdi East Road, Haidian District, Beijing.

FAQ

Q: What Sensors Work with Level Transmitter Boards?

A: ICwalk’s boards support various sensors, like ultrasonic transducers, magnetostrictive rods and capacitive probes. The choice depends on the model from ICwalk’s catalog.

Q: Can ICwalk Boards Be Used in Hazardous Areas?

A: Yes. Many boards have full electrical isolation up to 1000VDC between sensor and main circuit. This makes them safe for settings with flammable gases or corrosive chemicals.

Q: How Do I Calibrate an ICwalk Capacitive Level Transmitter?

A: The H509 has a three-button calibration feature. It also supports two-button mode. You can set span, zero offsets and adjust damping without extra tools or software.

Related Posts

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

What Role Do Level Transmitter Boards Play in Process Automation?

July 24,2025

-

How Does Technology Influence the Evolution of Modern Flow Transmitter Boards?

June 26,2025

-

What Role Does a Universal Temperature Transmitter Play in Heat Treatment?

June 12,2025

-

How Do TT Transmitters Optimize Temperature Monitoring Systems?

May 22,2025