What Is a Field Communicator and How It Improves Communication Flow

Understanding the Purpose and Function of a Field Communicator

What is a field communicator and why’s it a big deal in industrial settings?

A field communicator is a handheld gadget used to connect with smart field instruments in industrial automation setups. These include things like pressure transmitters, flow meters, temperature sensors and other process control gear. Its main job is to set up, calibrate, troubleshoot and maintain these devices quickly and easily.

In places like oil & gas, chemical plants, power stations, or metallurgy, where precision and keeping things running are crucial, field communicators are lifesavers. They let technicians check device settings right there on-site without taking stuff apart or stopping operations. This is huge for safety and getting work done fast.

How does a field communicator talk to smart field devices?

Field communicators link up with smart devices using digital protocols built for industrial use. These protocols allow two-way data swaps between the communicator and the instrument.

Overview of digital communication protocols in automation

Industrial automation uses standards like FOUNDATION Fieldbus, Profibus, Modbus and HART. HART (Highway Addressable Remote Transducer) is super popular because it works with older analog systems and supports advanced diagnostics.

The role of HART protocol in two-way communication

The HART protocol lets analog and digital signals run over the same wires at the same time. This mix keeps the 4–20 mA analog signal going for control while adding digital data for setup or troubleshooting.

HART375E supports the first master device of the HART (such as HART bridges) and also supports the point-to-point and multi-point communication modes of HART.

How Field Communicators Boost Communication Flow in Industrial Systems

In what ways do field communicators make data and diagnostics easier?

Field communicators make it way simpler to grab real-time data from instruments spread across a plant.

Real-time device status monitoring

Techs can check process details like pressure or temperature straight from the communicator without hitting up central control systems. HART375E intelligent handheld device can configure, calibrate and maintain all devices that comply with HART protocol, including setting the measuring range, loop testing, monitoring process variables and making on-site fine adjustments.

Better setup and calibration tools

Modern communicators have easy-to-use interfaces that make tweaking settings—like span adjustments or zero-point calibration—a breeze. Allows configuring various parameters of field devices. Engineers can adjust them easily through an intuitive interface to boost efficiency.

How does using a field communicator cut downtime and boost efficiency?

Streamlining setup and maintenance

Technicians can do initial setups or fix issues right at the site using a handheld communicator. In industries like petroleum, chemical, power and metallurgy, technicians use the H375 handheld for debugging, calibrating, configuring and diagnosing HART-protocol-based field instruments like pressure, temperature transmitters, flow meters and liquid level gauges.

Cutting down manual mistakes with user-friendly interfaces

With clear menus and graphical displays, modern communicators help operators avoid slip-ups during setup tasks. With an easy-to-use graphical interface and clear menu, it’s simple for non-professionals.

Exploring the HART Protocol and Its Role in Field Communication

What is the HART protocol and how does it work?

The HART protocol sends digital signals over old-school 4–20 mA analog wiring by layering frequency-shift keyed (FSK) signals on the current loop.

Analog signal with digital overlay explained

This mixed setup lets users send commands or grab diagnostic info digitally while keeping the analog output steady for control.

Compatibility with existing infrastructure

Since it uses standard wiring already in most plants, switching to HART systems doesn’t need major rewiring—saving serious cash.

Why is the HART protocol so popular in industrial automation?

Perks of hybrid analog-digital communication

It mixes real-time control via analog signals with cool features like remote diagnostics through digital messaging—giving flexibility without losing reliability.

Support for multiple manufacturers’ devices

HART works with gear from hundreds of manufacturers worldwide. This means one communicator can handle different brands of instruments across a whole plant.

Introducing ICwalk and the HART375E Intelligent Handheld Device

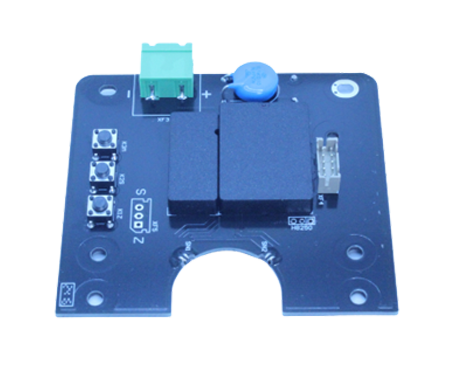

At ICwalk, we’ve built our star product—the HART375E intelligent handheld device—to meet the growing need for tough field communication tools.

What makes the ICwalk HART375E stand out among field communicators?

Compact design built for rough environments

Small and lightweight, easy to carry around. Battery-powered with long life, it meets on-site work needs. It’s made tough with anti-interference features to keep connections steady in noisy electrical settings.

High-resolution interface for easy use

With an easy-to-use graphical interface and clear menu, even less experienced users can navigate settings confidently under low-light conditions thanks to its backlit display.

Key features of the ICwalk HART375E intelligent handheld device

- Supports standard HART protocol fully including point-to-point/multi-point modes.

- Numeric shortcut keys for fast navigation during repetitive tasks.

- Automatic device polling on startup helps identify connected instruments quickly without manual input.

Practical Use Cases: Configuring Devices with the ICwalk HART375E

How do you connect and configure a device using the HART375E?

To start configuring:

- Hook up the cable from our handheld unit either directly to terminals or across load resistors.

- Make sure there’s at least 250Ω loop resistance, as the protocol needs.

- Turn on the unit; it’ll automatically find connected devices.

- Use shortcut keys or menus to tweak settings.

HART375E can be connected in parallel to HART devices or to their load resistors (250Ω). There is no need to consider the polarity of the leads when making the connection.

What types of operations can be performed with the ICwalk handheld communicator?

- Device identification, including model number retrieval.

- Access internal diagnostic codes for troubleshooting.

- Perform loop checks, zero/span calibration.

- Conduct self-tests ensuring transmitter integrity before commissioning.

FAQ

Q: What types of devices are compatible with a field communicator like the HART375E?

A: Any gear that follows the open-standard HART protocol—like pressure transmitters, level sensors, or flow meters—works with our product line.

Q: Can I use a field communicator to troubleshoot equipment issues on-site?

A: Yup. Our device pulls internal diagnostic codes from faulty instruments, so techs can figure out what’s wrong without yanking gear out of service.

Q: Is specialized training required to operate a handheld communicator like the ICwalk HART375E?

A: Nope. Our intuitive UI means even non-experts can use it with just a little guidance.

Q: What are the main benefits of using a field communicator in industrial settings?

A: Better insight into how instruments are performing, faster setup and configuration, less downtime with quick fault fixes and compatibility with tons of brands using standard protocols like HART.

Q: How does the ICwalk HART375E differ from traditional communicators?

A: It’s more portable (small size, long battery life), has better user interfaces (graphical menus), auto-polling features and supports both point-to-point and multi-drop setups right out of the box.

Q: Can one field communicator manage multiple types of devices?

A: Totally—if they use standard protocols like HART. Our ICwalk solution works smoothly with different manufacturers’ hardware across a plant.

Related Posts

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

What Role Do Level Transmitter Boards Play in Process Automation?

July 24,2025

-

How Does Technology Influence the Evolution of Modern Flow Transmitter Boards?

June 26,2025

-

How Can TT Temperature Transmitters Improve Process Control in Heat Treatments?

May 29,2025

-

What Are the Advantages of Using a Two-Wire Transmitter for RTD?

June 05,2025