What Are the Key Benefits of Using Flow Control Boards in Complex Systems?

Flow Control Boards in Complex Systems

What Is a Flow Control Board and How Does It Work in a Transmitter?

A flow control board is a vital part within electronic setups that controls the movement of data and signals, particularly in devices like transmitters. These boards serve as smart go-betweens between sensors and processors, making sure that details are sent correctly and effectively. In the setting of a transmitter, a flow control board handles elements such as signal timing, voltage control, and communication reliability.

To carry out these roles, the board usually contains analog-to-digital converters (ADCs), filters, and error fixing circuits. These parts change raw sensor info into digital signals, eliminate noise, and repair transmission mistakes before sending the data to control systems. This guarantees that the info received by the processing unit is pure, precise, and matched.

Why Are Flow Control Boards Essential in Complex Systems?

In setups with many parts, signal crowding or voltage unsteadiness can cause performance drop. Flow control boards lessen these dangers by managing traffic between parts, keeping system balance. They even out input/output movements to avoid data loss or system overloads and aid matching between sensors, processors, and output devices.

This matching is crucial in real-time industrial uses where even small delays or errors can cause big operational problems. By organizing how signals are handled and processed, flow control boards back steady system function even under changing environmental or working conditions.

Key Functional Benefits of Flow Control Boards for Transmitters

How Do Flow Control Boards Enhance Signal Accuracy?

Signal precision is key in uses like industrial flow gauging, where even tiny differences can have large effects. Flow control boards boost accuracy by reducing noise meddling using advanced filtering methods that raise the signal-to-noise ratio.

For example, the H8250FZ intelligent float transmitter board from ICwalk utilizes advanced signal processing technology to effectively eliminate interference signals, ensuring the accuracy of measurement results, with a measurement accuracy of up to ±0.35% (under standard conditions).

Additionally, these boards keep steady data sending across varying heat and voltage situations. This ability is especially vital in fields like aerospace or power creation where gear works in harsh settings.

Improving System Reliability Through Intelligent Regulation

Reliability in complex setups depends on clever control. Flow control boards adjust signal movement based on instant system feedback. This stops overworking of hardware parts by controlling voltage and current levels properly.

They also include fault spotting tools to separate issues before they grow into bigger breakdowns. The H880BR vortex flowmeter card from ICwalk includes Self-adaptive Spectrum Filtering (SSP) technologies, which help identify anomalies in signal processing. This real-time flexibility boosts operational safety and equipment lifespan.

Performance Optimization in Multi-Layered Architectures

What Role Do Flow Control Boards Play in Scalable System Design?

Modern industrial arrangements often grow over time. A scalable design must handle extra transmitters or sensors without major rewiring or software alterations. Flow control boards allow this bendability by backing modular blending.

They also back multiple communication rules—such as HART, RS485, and Modbus—that permit centralized or spread control based on application needs. For instance, the E4000 electromagnetic flow transmitter board from ICwalk supports RS232/RS485 communication based on the MODBUS RTU protocol and optionally HART communication.

By making communication and setup ways standard, these boards ease system growth and lower blending complexity.

Enhancing Efficiency in Industrial Applications

Flow control boards are broadly used across fields due to their skill to guarantee efficiency and precision. In automation setups, they organize instant communication between sensors and controllers for exact process handling. In telecommunications, they control high-speed data routing with little delay.

In high-risk settings such as aerospace, they keep signal wholeness despite heat extremes or electromagnetic meddling. ICwalk’s H837FZ micro-flow metal-tube transmitter is engineered for high-performance HART protocol mini-flow rotameter transmitters and is ideal for applications demanding precise and stable flow measurement.

Integration Challenges and Solutions with Flow Control Boards

What Are Common Integration Issues When Using Flow Transmitter Boards?

Despite their perks, blending flow control boards into current setups may bring challenges. One usual problem is matching with old parts that use dated interfaces or communication rules. Another issue could be calibration mismatches between sensors and transmitter boards, leading to uneven readings.

Power supply unevenness also brings risks; poor voltage control can result in unsteady function or hardware harm. These problems are particularly tough in spread setups where transmitters are placed across big sites.

Solutions to Improve Integration Success Rate

To tackle these challenges, system planners should use best ways during planning and rollout. Using standard interfaces like SPI or I2C simplifies links with various sensor kinds. Pre-testing setups under mimicked conditions lets spotting of possible blocks before full rollout.

Firmware bendability is also key. ICwalk’s products come with configuration software that backs one-stop calibration and startup, streamlining development cycles from design to mass production. This permits firmware updates to match changing system needs and guarantees long-term flexibility.

ICwalk’s Contribution to Advanced Flow Control Technology

What Makes ICwalk’s Flow Transmitter Board Stand Out?

At ICwalk, we focus on providing high-precision flow control answers made for tough industrial settings. Our flow transmitter boards match both analog and digital setups and are relied on by over 800 instrument makers across varied sectors such as oil & gas, pharmaceuticals, and environmental tracking.

ICwalk transmitter boards are trusted by over 800 instrument manufacturers in China, with extensive field validation. Fully compatible with mainstream protocols like HART and PROFIBUS-PA, our products match global standards, ensuring smooth integration and easy export.

We offer exceptional customization capabilities—over 200 tailored solutions delivered—covering pressure, temperature, level, and flow sensing applications. With built-in diagnostics and monitoring features, our boards enable real-time evaluation of system performance and health.

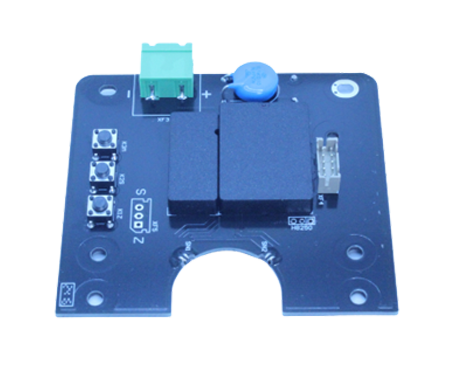

Key Features of ICwalk’s Flow Control board for Transmitter You Should Know About

Our flow transmitter boards feature multi-protocol communication support (UART, Modbus), voltage regulation circuitry for consistent power delivery across varied loads, and a compact design ideal for embedded applications.

The H8250FZ offers 4~20mA signal output with HART (2-wire), LCD display of instantaneous/cumulative flow values simultaneously, local configuration capabilities including alarm settings, and built-in power-off protection.

With patented algorithms and ongoing R&D, our solutions keep you ahead of industry trends, supporting your product’s technical evolution.

FAQ

Q: What is the main function of a flow control board in a transmitter system?

A: A flow control board regulates the flow of signals within a transmitter system, ensuring accurate data transmission, reducing noise, and improving overall reliability.

Q: Can I use a flow control board with both analog and digital transmitters?

A: Yes, many modern flow control boards—such as those from ICwalk—are designed to work with both analog and digital systems through adaptable interfaces.

Q: How do I know if my system needs a dedicated flow control board?

A: If your system experiences frequent data errors, inconsistent signal timing, or struggles with multi-component synchronization, adding a flow control board can significantly improve performance and stability.