How to Ensure Longevity of Pressure Control Boards in Transmitters?

The Function of Pressure Control Boards in Transmitters

What Role Do Pressure Control Boards Play in Transmitter Systems?

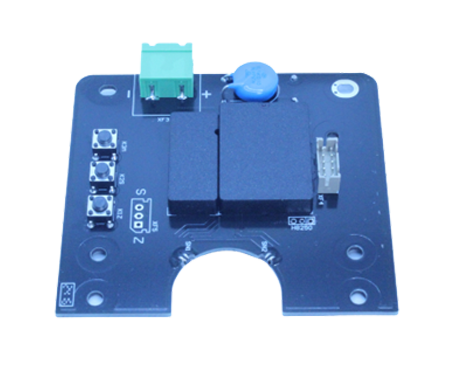

Pressure control boards act as the vital connection between pressure sensors and output electronics in contemporary transmitter setups. These boards process the analog or digital signals from the pressure sensing element. They handle signal conditioning too. Then, they deliver a precise, steady output to monitoring or control systems.

A pressure transmitter includes several main parts: Pressure Sensor, Transducer, Signal Conditioning Circuitry, Output Interface and Enclosure. The pressure control board combines most of the signal processing elements. This includes amplification, filtering and temperature compensation.

These boards are crucial for keeping signal quality intact during changing conditions. The raw electrical signal from the transducer often needs adjustment. This makes it more precise, reliable and ready for handling. Without this board, signal precision would suffer from electrical interference or outside disruptions.

Why Is Longevity Important for Pressure Control Boards?

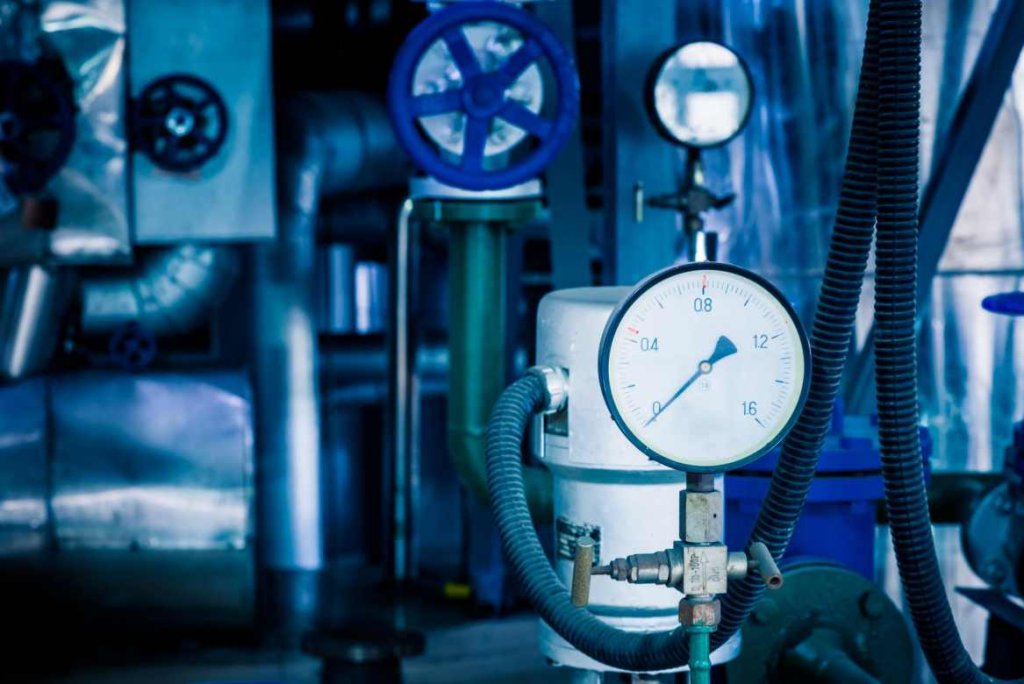

The toughness of pressure control boards greatly affects the dependability of whole transmitter systems. In vital industrial settings—like oil & gas, pharmaceuticals and marine operations—dependability guarantees ongoing monitoring in key uses. If the board fails, it might cause shutdowns, operation mistakes, or safety hazards.

Longevity also lowers the overall cost of owning the system. Durable boards cut down on repair needs and swaps. As a result, they reduce downtime and upkeep expenses. This proves especially useful in isolated or risky spots where fixing things is tough and expensive.

Key Factors That Affect the Lifespan of Pressure Control Boards

How Do Environmental Conditions Influence Board Durability?

Pressure control boards frequently work in tough industrial spots. The enclosure shields the delicate inner parts of the pressure transmitter from outside elements like moisture, dust, temperature shifts and physical harm. Yet, without good protection, contact with harsh gases, moisture buildup, or tiny particles can wear down circuit lines and parts.

Heat stress from very high or low temperatures can crack solder connections or ruin components. To fight this, we at ICwalk use protective coatings. They successfully stop harm to electronic parts from the outer surroundings.

Strong sealing and case design are essential. Our H3051 series transmitters feature sturdy enclosures. They function well from -40℃ to +85℃ based on display setup.

The Impact of Electrical Stress on Circuit Longevity

Power issues can seriously shorten a board’s life. Sudden voltage jumps and current rushes might ruin chips and other fragile parts forever. Our boards come with anti-jamming tools like strong TVS (Transient Voltage Suppressor) and magnetic beads inside. They efficiently block various on-site disturbances.

Bad grounding can also bring in extra noise or feedback cycles that mess up regular work. At ICwalk, our setups include surge safeguards and steady power circuits. These help prolong working life.

Plus, our EEPROM has an improved anti-jamming setup. It offers full data backup and recovery options. This fully enables no-maintenance use right on site.

Best Practices for Ensuring Long-Term Performance of Pressure Control Boards

What Maintenance Routines Should Be Followed?

Regular upkeep boosts board durability a lot. Start with visual checks for rust, color changes, or broken solder spots. Dust accumulation can block heat escape and cause part breakdowns. So, frequent cleaning is advised.

Calibration stands as another vital job. It makes sure the pressure transmitter gives exact and trustworthy readings. This happens by tweaking the output signal to fit known standard pressures. At ICwalk, we provide HART-Tool setup software. It lets you easily and quickly adjust the sensor’s measurement range and the transmitter’s range.

Installation Tips to Maximize Board Lifespan

Proper Mounting Techniques

Mount boards firmly with shock-absorbing holders if needed. This cuts down on wear to solder joints and plugs from shaking.

Optimal Placement Within Enclosures

Position boards clear of heat-producing items like power changers or transformers. Smart heat control avoids gradual breakdown.

Cable Management Practices

Neat cabling not only boosts air flow but also eases pressure on connections. These spots often fail from bending or sudden pulls.

Material Quality and Manufacturing Standards Matter

How Does Component Quality Affect Longevity?

Part quality forms the base. Top-quality capacitors, resistors and ICs handle wider voltage and temperature ranges. Pressure sensors usually have circuits to adjust the basic signal from the sensing part. If these elements are low-grade, they can cause shifts or full breakdowns as time goes on.

Exact soldering counts as another key point. Weak solder links lead to many failures under shaking or heat changes. Our production methods use automatic making and checking systems. Together with electronic barcode following, they assure solid work for each board. This holds true even in big runs.

Importance of Manufacturing Consistency in Board Performance

Steady production ensures trust across devices. Differences in solder work or part positioning can hide flaws. ICwalk applies strict quality checks in putting together and testing.

Automatic checks in making spot possible issues early. This lowers failures in the field. It also builds trust for use in crucial tasks.

The Role of ICwalk in Reliable Pressure Transmitter Boards

What Makes ICwalk’s Pressure Transmitter Board Stand Out?

Our transmitter boards focus on toughness and strong output in hard situations. We design them with industrial-grade parts for great strength and steadiness. They work with common protocols like HART and PROFIBUS-PA. This allows simple fitting into worldwide systems.

Our items meet world standards. So, they blend in smoothly and export easily. Also, our tools aid fast setup and testing: Full setup software and tools handle all calibration and startup in one go.

How Does ICwalk Address Common Longevity Challenges?

We apply smart PCB design methods to cut hot areas and lower EMI dangers. Better PCB layouts reduce heat pileup and power disruptions.

To guard against outside threats like dampness or salt mist, shielding layers protect circuits from water, dirt and rust dangers. Paired with our anti-jamming traits and EEPROM backups, this creates a strong base fit for any factory use.

FAQ

Q: How often should a pressure control board be calibrated?

A: Calibration should typically be performed annually or as recommended by the manufacturer, especially if used in high-stress environments.

Q: Can a damaged pressure control board be repaired, or should it be replaced?

A: Minor issues like connector faults can sometimes be repaired, but significant damage to circuitry usually requires replacement to ensure reliability.

Q: What are common signs that a pressure control board is failing?

A: Symptoms include inconsistent signal output, increased noise levels, overheating, or complete signal loss from the transmitter system.