How to Assemble an Instrument Production Line for Peak Efficiency

What Are the Main Steps to Set Up an Instrument Production Line?

Getting an instrument production line up and running like a well-oiled machine takes a solid plan, the right tech and skilled folks. From grabbing raw materials to final quality checks, every step needs to be dialed in to keep things humming with minimal hiccups.

Why’s Workflow Planning a Must for Instrument Manufacturers?

For any instrument manufacturer, nailing the workflow is the backbone of getting stuff done right. A smart setup cuts down on bottlenecks, keeps parts coming on time and matches production to what the market wants. Without a clear plan, you’re looking at delays, wasted materials and spotty product quality. A good workflow also makes it easier to scale up or tweak things as your product lineup grows.

Key Pieces of a Smooth Assembly Process

Procurement and Inventory Management

Smart procurement makes sure you’ve got all the parts—like sensors, transmitter boards and housings—ready when you need ‘em. Inventory systems should tie into forecasting tools to avoid having too much or too little stock. Just-in-time (JIT) strategies can cut storage costs while keeping materials on hand.

Workstation Design and Layout

How you set up the assembly line matters big-time for productivity. Arrange workstations in a logical flow—soldering, calibration, casing, testing—to cut out extra steps. Ergonomic setups also keep workers comfy and reduce mistakes from being worn out.

Quality Control Checkpoints

Weaving quality control (QC) into key spots—like testing after assembly or checking before packing—catches issues early. This stops faulty instruments from reaching customers and saves on rework costs. Automated QC systems with vision sensors or digital gauges can boost accuracy.

How Can Automation Make Instrument Manufacturing Better?

Automation is a game-changer for cranking out complex assemblies like transmitters and field instruments with speed and precision.

Role of Robotics and Automated Testing

Robots handle repetitive jobs like placing parts or soldering with lightning speed and consistency. Automated testing rigs mimic real-world conditions to check sensor outputs for stuff like temperature, pressure, flow, or level before shipping.

Cutting Human Errors with Smart Systems

Smart manufacturing systems use sensors, software and feedback loops to keep an eye on things in real time. They ping operators about weird stuff right away, cutting down on mistakes and letting folks fix issues before they snowball.

Which Teams and Skills Make a Production Line Rock?

Building a killer instrument production line isn’t just about gear—it’s about people with the right know-how working together like a tight crew.

What Roles Are Key for a Top-Notch Production Team?

Engineers and Technicians

Engineers map out the production process, while technicians tackle tasks like wiring ICwalk transmitter boards or calibrating sensors. Their skills make sure instruments hit functional and safety standards.

Quality Assurance Specialists

QA folks set up inspection routines throughout the production cycle. They check that each unit nails specs for accurate temperature or pressure readings.

Supply Chain Coordinators

These pros handle vendor relationships and logistics to keep parts like transmitter boards or enclosures rolling in on time. They also deal with customs paperwork for international sourcing.

How Do Training and SOPs Boost Performance?

Why Consistent Skills Matter

Standardized training makes sure every technician does things the same way, no matter the shift or location. This keeps output quality steady across batches.

Crafting Clear SOPs for Each Product

Every instrument type—from flow meters to level sensors—needs its own SOP laying out assembly steps, calibration methods and test standards. These guides are handy for onboarding or audits.

What Makes ICwalk a Go-To Partner for Instrument Manufacturers?

As a trusted provider of high-performance ICwalk transmitter boards and diagnostics tools, we at ICwalk back over 800 instrument manufacturers across China with reliable, tailored solutions for modern instrumentation needs.

Who’s ICwalk and What Do They Bring to the Table?

We specialize in modular ICwalk transmitter boards that work with mainstream protocols like HART and PROFIBUS-PA, ensuring they slot right into your systems.

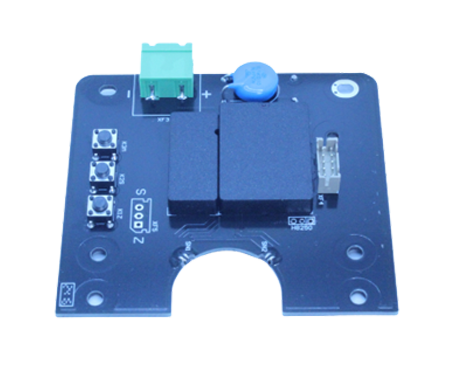

ICwalk’s Expertise in Transmitter Boards

We’ve delivered 200+ customized solutions for 800+ manufacturers, supporting a wide range of sensors (pressure, temperature, level, flow). Whether you need analog signal processing or digital interfaces, our designs fit your needs like a glove.

Compatibility with Modern Systems

All our products play nice with industrial automation setups using standard protocols, making deployment a breeze without compatibility headaches. Quickly assemble high-performance, cost-effective local brand instruments and accelerate your time-to-market.

How Do ICwalk Products Boost Production Efficiency?

Temperature Transmitter Board: Spot-On Thermal Readings

Our temperature boards stay steady in all kinds of conditions, perfect for HVAC systems or industrial furnaces.

Pressure Transmitter Board: Rock-Solid Under Changing Loads

These boards give consistent pressure readings even when loads shift, crucial for hydraulic systems or chemical reactors.

Flow Transmitter Board: Nailing Fluid Dynamics

Our flow modules deliver reliable readings, even at low flow rates, great for lab-grade devices or industrial setups.

Level Transmitter Board: Trusty Liquid Level Sensing

They are ideal for monitoring tanks with water-based or thick fluids with high repeatability.

Field Communicator: Easy Device Setup and Diagnostics

Our field communicators give centralized access to device settings across multiple instruments, speeding up setup and cutting configuration errors.

Enjoy responsive one-on-one service from our expert engineers—ensuring rapid issue resolution and smooth project delivery.

Why Should Manufacturers Team Up with ICwalk?

Boosting Modularity and Interoperability

Our modular setup lets you mix-and-match parts without overhauling your whole system—a big win for customizing instruments for niche markets. ICwalk transmitter boards are trusted by over 800 instrument manufacturers in China with extensive field validation.

Cutting Downtime with Reliable Tools

With solid protocol support baked into every board, we help avoid communication glitches that can lead to pricey downtime. Get advanced solutions at competitive prices empowering your instrument products to stand out in local markets.

How Can Data Analytics Amp Up Production Line Performance?

Data-driven decisions change how instrument manufacturers run their lines, from managing resources to scheduling maintenance.

What Metrics Should You Track on the Floor?

Key stuff to watch includes yield rates (percentage of defect-free units), cycle times (how long each unit takes), defect ratios (number of faulty units), machine uptime percentages and worker productivity per shift.

Using Real-Time Dashboards to Make Smarter Calls

Dashboards pull live data into easy-to-read visuals that show trends right away, letting supervisors jump on issues or dips in performance fast.

Common Hurdles in Setting Up an Instrument Production Line

Even with top-notch planning, instrument manufacturers hit snags that can throw off timelines or mess with product quality.

What Are the Usual Bottlenecks?

Delays in Getting Parts

Global supply chain hiccups can hold up critical components like PCBs or sensors, slowing down the whole line if you don’t have enough stock.

Inconsistent Standards Across Shifts

Day and night shifts can vary unless you’ve got standardized training to keep everyone on the same page.

How to Tackle Downtime and Maintenance Issues?

Predictive Maintenance Strategies

Using IoT sensors on machines spots wear-and-tear early, letting you schedule maintenance instead of dealing with surprise breakdowns.

FAQ

Q: What’s the first step when setting up an instrument production line?

A: Start with detailed workflow planning which defines process sequences from component sourcing through final QC inspection stages.

Q: Which team members are most essential during line setup?

A: Engineers design processes; technicians handle assembly; QA specialists ensure compliance; supply coordinators manage logistics—all roles are vital for success.

Q: Why should I consider partnering with ICwalk?

A: ICwalk transmitter boards are trusted by over 800 instrument manufacturers in China, offering fast assembly capabilities along with international-grade compatibility like HART/PROFIBUS-PA support.

Q: How do I reduce downtime during production?

A: Use predictive maintenance tech and real-time monitoring dashboards to catch issues before they cause breakdowns.