How Does Technology Influence the Evolution of Modern Flow Transmitter Boards?

What Are Flow Transmitter Boards and Why Are They Important?

Understanding the Basics of Flow Transmitter Boards

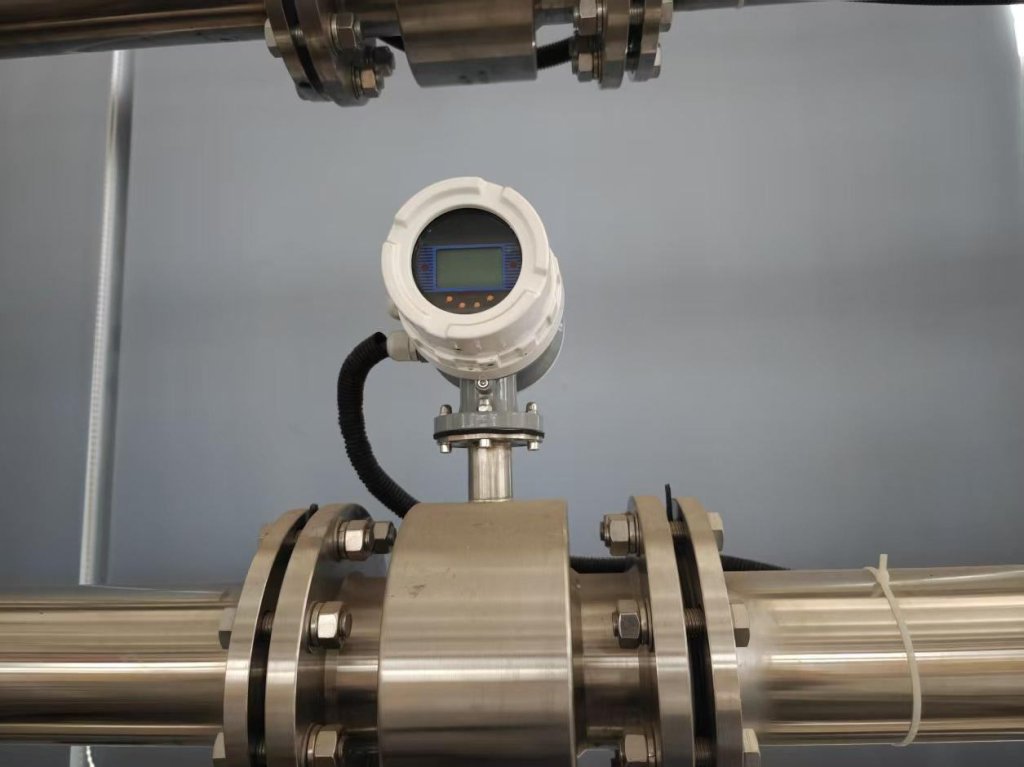

Flow transmitter boards are essential parts of industrial measurement systems. They are built to track and manage the movement of liquids and gases. These boards handle signals from sensors to deliver precise flow data, which ensures smooth system operation.

For example, the H8250FZ intelligent flow transmitter board is designed for high-performance metal rotameters. It offers advanced features like HART protocol support. Their role spans many industries where accuracy and dependability are critical.

Why Do Industries Rely on Flow Transmitter Boards?

Industries depend on flow transmitter boards because they provide accurate measurements in varied conditions. The H8250FZ board, for instance, achieves a measurement precision of up to ±0.35% under normal conditions. This accuracy supports efficient resource use and system reliability.

Applications include city water systems, chemical manufacturing, environmental monitoring and agricultural irrigation. The adaptability of these boards makes them vital for operational efficiency.

How Do Flow Transmitter Boards Enhance Measurement Accuracy?

Flow transmitter boards use cutting-edge technologies to ensure precise measurements. The H8250FZ board employs advanced signal processing methods. These methods remove interference signals. This ensures consistent readings in complex industrial settings.

Additionally, quick response times enable real-time monitoring of fluid dynamics. This makes these devices crucial for operations needing instant adjustments.

How Has Technology Shaped the Development of Modern Flow Transmitter Boards?

What Technological Advancements Have Impacted Flow Transmitter Boards?

The growth of flow transmitter boards has been driven by progress in electronics and communication protocols. At ICwalk, we provide products like E4000 electromagnetic flow transmitter boards and vortex flow transmitters. These products showcase innovations such as built-in digital displays and improved connectivity options. The trend toward smaller designs has also allowed compact solutions without sacrificing performance.

The Role of Digital Integration in Modern Flow Transmitter Boards

The Shift from Analog to Digital Systems

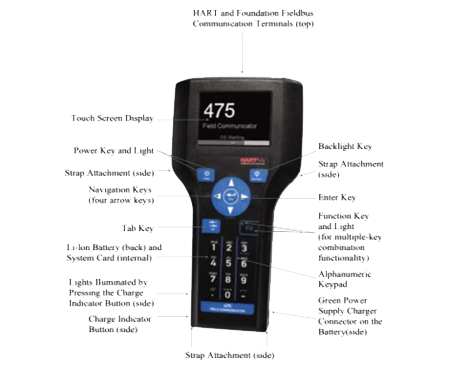

Digital integration has changed traditional analog systems into highly responsive digital platforms. This shift improves data processing and allows smooth integration with modern monitoring systems. Our smart metal tube rotor flow transmitters demonstrate this change, including features like HART communication protocol. Such advancements ensure compatibility with advanced industrial systems.

Real-Time Data Transmission Capabilities

Real-time data transmission is a key feature of modern flow transmitter technology. By using digital communication protocols like RS485 and Modbus RTU, these devices enable instant data sharing across networks. For example, ICwalk’s ultrasonic open channel flow transmitters support 4-20 mA output and RS485 communication, which ensures accurate monitoring and improves decision-making by providing timely and reliable system performance insights.

Key Features of ICwalk’s Flow Transmitter Board

What Sets ICwalk’s Flow Transmitter Board Apart?

High Precision Measurement and Stability

ICwalk’s H8250FZ board excels with its high measurement accuracy (±0.35%). This is achieved through advanced signal processing. Its stability ensures reliable performance in tough environments. It reduces errors caused by external factors like temperature changes or vibrations.

Compatibility with Advanced Monitoring Systems

Our products are designed to work seamlessly with modern industrial setups. For instance, the E4000 series supports communication protocols like HART and RS485. This flexibility allows users to integrate our boards into existing systems without major changes.

How Does ICwalk Ensure Quality in Its Products?

At ICwalk, quality is a core part of our production process. We use strict testing methods to ensure each product meets industry standards for accuracy and durability. Our facilities are located at Room 701, Building 1, No. 1 Shangdi East Road in Beijing. They are equipped with advanced technology to drive innovation. By valuing customer feedback and constant improvement, we uphold our reputation as a trusted global provider of flow transmitter solutions.

The Role of IoT and Automation in Evolving Flow Transmitter Boards

How Is IoT Transforming the Functionality of Flow Transmitter Boards?

Remote Monitoring and Control Features

The addition of IoT to flow transmitter boards has transformed how industries monitor and manage fluid dynamics. IoT allows these boards to send real-time data to central systems. This enables remote oversight of operations. For example, ICwalk’s ultrasonic open channel flow transmitters use RS485 communication protocols. They provide precise monitoring capabilities. This is especially useful in industries like municipal water management and environmental protection, where quick actions are essential.

IoT also supports predictive maintenance. It analyzes data trends to predict equipment failures. This reduces downtime and boosts efficiency. At ICwalk, our products include these advanced features to meet modern industry needs.

Enhanced Connectivity Across Industrial Networks

Connectivity is a key aspect of IoT-enabled flow transmitter boards, which ensures smooth integration into existing industrial networks. Our intelligent metal tube rotor flow transmitters highlight this connectivity, which enables real-time data sharing across multiple systems and improves decision-making.

Moreover, enhanced connectivity supports interoperability between devices in an industrial setup. This ensures that data from flow transmitter boards can be accessed and analyzed alongside other metrics. It provides a complete view of system performance.

What Is the Impact of Automation on Performance Efficiency?

Automation has greatly improved the efficiency of flow transmitter boards. It reduces human involvement and minimizes errors. Automated systems process large amounts of data quickly and accurately. This ensures optimal resource use. For example, the H8250FZ board offers high measurement accuracy (±0.35%). This is achieved through advanced signal processing. Such precision is vital for industries like chemical production and pharmaceuticals.

Additionally, automation improves the responsiveness of these boards. Fast response times allow real-time adjustments to fluid dynamics. This ensures consistent performance under changing conditions. At ICwalk, we focus on including automation features in our products. This delivers reliable and efficient solutions.

Challenges in the Evolution of Modern Flow Transmitter Boards

What Are the Common Issues Faced by Manufacturers?

Balancing New Ideas with Affordability

A huge hurdle in creating modern flow transmitter boards is keeping new ideas affordable. Features like IoT connectivity and automation are great. But they often raise production costs. Makers need to find ways to add these technologies. They must do this without making products too pricey for customers.

At ICwalk, we tackle this challenge by streamlining our production processes. We also leverage economies of scale. Our range includes affordable options like battery-powered vortex flow transmitters. These still deliver reliable performance. This approach ensures our products are accessible while meeting industry standards.

Ensuring Durability in Harsh Environments

Flow transmitter boards are often used in tough environments. They face extreme temperatures, humidity and corrosive substances. Ensuring durability in these conditions is a significant challenge. The H8250FZ board addresses this with excellent long-term stability. It maintains consistent performance in complex industrial settings.

To improve durability, ICwalk uses strong materials and thorough testing during production. Our commitment to quality ensures our products can handle harsh environments. They maintain accuracy and reliability.

How Can Companies Like ICwalk Address These Challenges?

At ICwalk, we take a proactive approach to overcoming challenges in modern flow transmitter boards. Our focus on research and development keeps us ahead of industry trends. It allows us to deliver innovative solutions tailored to customer needs.

We also value customer feedback as a key part of our product development. By understanding the unique needs of different industries, we design effective products.

FAQ

Q: What are flow transmitter boards used for?

A: Flow transmitter boards monitor and control the flow of liquids and gases in industrial applications. They process sensor signals to provide accurate flow measurements. These are essential for system efficiency.

Q: How does IoT enhance flow transmitter functionality?

A: IoT improves functionality through remote monitoring, predictive maintenance and real-time data transmission across networks. These features boost efficiency and reduce downtime.

Q: What makes ICwalk’s products stand out?

A: ICwalk’s products are known for their high-precision measurements, advanced connectivity and durable designs that are suitable for harsh environments. We offer a wide range of models for various industrial needs.

Related Posts

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

What Role Do Level Transmitter Boards Play in Process Automation?

July 24,2025

-

What Makes the Flow Transmitter Board Crucial for Precise Data Transmission?

July 17,2025

-

How to Evaluate the Reliability of a Pressure Transmitter Board Under Stress?

July 03,2025