How Can Understanding Temperature Transmitter Functionality Improve Heat Treatment Efficiency?

What is a Temperature Transmitter and How Does it Work?

The Basics of Temperature Transmitters

Industrial operations rely heavily on temperature transmitters to gauge and translate temperature readings into a format for monitoring and regulation purposes in various processes. These devices operate by taking inputs from temperature sensors such as thermocouples (TC) or resistance temperature detectors (RTDs), which detect shifts in temperature and deliver signals for the transmitter to interpret into a suitable format for integration with control systems.

How Do Temperature Transmitters Convert Signals?

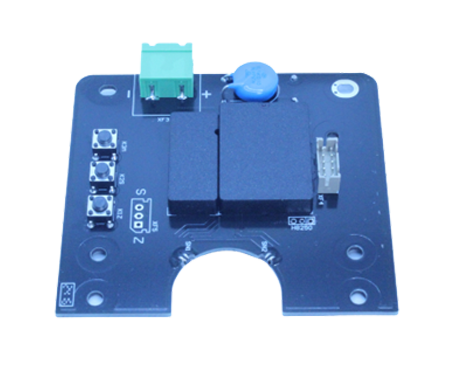

The H648WD series temperature transmitters manufactured by ICwalk are designed to convert signals from thermocouples or RTDs in the field into a 4 20mA current output that corresponds to temperature in a linear manner. These transmitters are versatile. Can accommodate various types of RTDs such as Pt50

Why Are Temperature Transmitters Essential in Industrial Processes?

Temperature sensors are essential for keeping processes running smoothly and safely by delivering precise, real-time temperature data that allows for precise control of operations and systems. This helps maintain the quality of products while also cutting down on waste and energy usage efficiently.

Our advanced temperature sensor model H3051WD is known for its accuracy and includes features like compatibility with the HART protocol for remote monitoring and enhanced stability.

The Role of Temperature Transmitters in Heat Treatment Efficiency

How Does Accurate Temperature Monitoring Enhance Heat Treatment?

In order to achieve the desired material properties such as hardness or ductility through heat treatment processes, it is essential to maintain temperature control throughout the cycles of heating and cooling with accurate monitoring to prevent material defects effectively.

Our H648WD series is designed to provide a level of output accuracy of 0.d 1% specifically for RTD inputs and comes equipped with features, like adjustable damping to optimize response times as needed. This meticulous attention to detail directly influences the uniformity and dependability of the finished heat-treated products.

What Are the Key Benefits of Using a High-Quality Temperature Transmitter Like ICwalk’s Products?

Improved Process Control with ICwalk Temperature Transmitters

ICwalk’s H3051WD offers enhanced functionalities like field adjustment options for setting ranges and tuning zero and sensor adjustments to cater to various specific needs of users or applications. Moreover, its adjustable LCD screen makes it convenient for installation or upkeep tasks.

Reducing Energy Consumption Through Precise Measurements

Accurate measurements help minimize energy wastage by tuning heating cycles effectively. Our devices also feature a display that shows multiple variables with backlighting for situations with low lighting. This feature enables operators to promptly make well-informed decisions, which in turn reduces downtime and energy consumption

Types of Temperature Transmitters and Their Applications

What Are the Different Types of Temperature Transmitters?

Analog vs. Digital: Which One Suits Your Needs?

Analog transmitters continuously transmit signals. Do not have the advanced communication features found in digital models like the ones from ICwalk, which include protocols like HART to improve functionality. The H648WD transmitter we offer combines analog 4–20mA outputs with modern digital communication capabilities.

Wired and Wireless Options for Industrial Use Cases

In situations where reliable connections are needed wired transmitters are often preferred over alternatives due to their stability and consistency even though wireless options provide flexibility in remote locations but can be susceptible to disruptions in signal quality and performance issues occasionally occurring ICwalk’s product range features dependable wired solutions, with durable constructions that guarantee consistent functionality even in demanding environments and circumstances.

Where Are ICwalk’s Temperature Transmitters Commonly Used?

ICwalk’s temperature transmitters are used in industries like chemical processing, power generation, metallurgy and food production. One example is our H649WD model, which is designed for DIN rail installation in setups. These instruments perform well in settings that demand precision and resilience.

By gaining insight into the operations of temperature transmitters and how they contribute to boosting the efficiency of heat treatment processes, industries can greatly improve performance and cut down on expenses incurred. ICwalk is dedicated to delivering cutting-edge solutions customized to address a range of industrial requirements.

Choosing the Right ICwalk Temperature Transmitter for Your Needs

Factors to Consider When Selecting a Temperature Transmitter

Input Types: RTD, Thermocouples and Others

When you’re choosing a temperature transmitter, it’s important to know what kinds of inputs it can handle effectively. It’s common to find Resistance Temperature Detectors (RTDs) and Thermocouples (TCs) being widely used in settings.

ICwalk’s H648WD series is designed to work with types of RTDs such, as Pt50, Pt100, Pt200, Pt500, Pt1000, Cu10, Cu50 and Cu100 sensors. Moreover, it is compatible with thermocouples of types such as E, J, B, K, N, R, S, T, DIN L, WGOST L. This wide range of compatibility allows for versatility in industrial environments.

The H648WD series provides options, for connecting RTDs. You can choose between two wire two wire two wire or four wire setups to match your needs perfectly. For connections, the device has a built in feature that compensates for cold junctions to ensure temperature readings are accurate. These functions simplify the process of monitoring heat treatment procedures.

Output Signals: Current, Voltage, and Digital Protocols

When choosing an output signal type to consider the type of signal is essential to note that ICwalk’s H648WD that corresponds to temperature readings accurately. This standard signal format guarantees integration with a wide range of control systems. Moreover, the equipment features HART protocol communication for digital interactivity without interfering with the analog signal transmission.

The resistance load of less than (the input voltage minus 10) divided by is equivalent to 4 ohms. Improves its flexibility in different industrial settings, especially useful for accurate signal transmission over extended distances or in environments with electrical interference.

Why Should You Choose ICwalk for Advanced Solutions?

ICwalk is recognized for its excellence in temperature transmitter technology thanks to its dedication to creativity and excellence, in quality control measures ensuring that our products are tailored to meet user preferences and industrial requirements as evidenced by the following instance;

- High Accuracy: The H3051WD model provides an accuracy of 0.1% for RTD inputs.

- Durability: With an operating temperature range of -40°C to +85°C and relative humidity tolerance of 10% to 90%, our devices are built for harsh environments.

- Advanced Features: The H3051WD includes field adjustment functions such as zero trim and sensor trim for enhanced customization.

Our transmitters are designed with isolation abilities of up to DC1000 volts to shield against electrical disturbances and ensure consistent performance reliability.

Common Challenges in Heat Treatment Processes Addressed by ICwalk Products

How Do ICwalk’s Devices Help Overcome Calibration Issues?

Calibration issues often arise in heat treatment procedures because of changing conditions or inaccuracies in sensor readings. To mitigate these challenges effectively, ICwalk’s smart transmitters come into play well. For example, our H648WD line guarantees an output precision of 0.01 percent for RTDs. Incorporates cold junction compensation with a mere 1 degree Celsius margin of error.

Furthermore, our devices are capable of being managed through handheld devices or PC software using the HART Configuration tool. This feature makes it easier to troubleshoot and make calibration adjustments without the need for on-site assistance.

Preventing Signal Interference with ICwalk’s Advanced Technology

Interference from signals can greatly affect the precision of temperature readings, in environments prompting the need to address this challenge effectively.

- Electrical Isolation: Our transmitters feature isolation voltages up to DC1000V. This high level of isolation protects against electrical noise and ensures stable signal transmission.

- Anti-Disturbance Features: The H3051WD model incorporates military-grade protection against over-voltage surges and electrostatic discharge.

- Adjustable Damping: Users can fine-tune response times from 0 to 32 seconds based on application needs.

In settings such as metallurgy or chemical processing plants, these advancements improve dependability.

FAQ

Q: What Is the Role of Cold Junction Compensation?

A: Cold junction compensation helps adjust for changes in temperature at the spot where a thermocouple connects to a transmitter, ensuring readings are even when the external temperature changes, with ICwalk’s equipment featuring built-in cold junction compensation capabilities to maintain precision regardless of outside temperature shifts.

Q: How Does Understanding Temperature Transmitter Functionality Improve Heat Treatment Efficiency?

A: Understanding the functionality of transmitters is crucial in optimizing heat treatment processes in industries as they convert sensor signals into outputs effectively to enhance material quality through consistent heating cycles.

Q: Why Are Digital Communication Protocols Important?

A: Protocols such as HART allow for monitoring and remote adjustment of transmitters, which helps minimize downtime during maintenance and maintains optimal operational performance.

We strive to offer solutions customized to address a variety of industrial requirements by incorporating cutting edge functionalities into our offerings at ICwalk.com, specifically on our temperature transmitter board page.

Related Posts

-

What Are the Key Features of Advanced Pressure Transmitter Boards?

August 07,2025

-

How Do Innovations in Temperature Transmitter Boards Impact Market Trends?

July 31,2025

-

What Role Do Level Transmitter Boards Play in Process Automation?

July 24,2025

-

How Does Technology Influence the Evolution of Modern Flow Transmitter Boards?

June 26,2025

-

What Makes the Flow Transmitter Board Crucial for Precise Data Transmission?

July 17,2025