Integrating Sensors with a Process Control Board Transmitter: Best Practices for Reliable Signal Transmission

¿Qué es un transmisor de placa de control de procesos y por qué importa?

Process control board transmitters serve as the quiet champions in industrial automation. They capture signals from sensors—such as temperature, pressure, flow, or level—and transform those basic readings into standard outputs like 4–20mA or digital standards including HART or Modbus. This step proves vital. It guarantees that control systems and operators get precise, steady data for smart choices.

How Does a Process Control Board Transmitter Work?

A process control board transmitter operates by changing raw sensor inputs into practical communication forms. For example, if you use a thermocouple to track heat in a furnace, the transmitter reads the changing voltage from the thermocouple. Then, it turns that into a standard signal.

It provides exact communication between field devices and control systems. This allows real-time watching and careful tweaks. Such features are key for keeping efficiency in automated tasks.

Why Is Signal Reliability So Important in Process Control?

In risky settings like oil refineries or drug production, shaky signals can cause big problems. Unsteady signals might result in wrong readings. This could set off alarms or halt operations without need.

Steady transmission boosts safety, productivity, and item quality. Plus, dependable signal paths help avoid expensive stops. They make sure systems run well and without hitches.

Choosing the Right Sensor for Your Application

What Types of Sensors Can Be Integrated with a Transmitter Board?

Many kinds of sensors can link up with transmisores de placa de control de procesos:

- Temperature sensorslike RTDs (Resistance Temperature Detectors) or thermocouples.

- Pressure sensors, common in gas lines or hydraulic setups.

- Flow sensorsto track the speed of liquid or gas flow.

- Level sensors, such as capacitive or ultrasonic types, perfect for tanks or silos.

For example, our ICwalk H648WD temperature transmitter board handles both RTD and thermocouple inputs. It gives a linear 4–20mA current isolated output that matches temperature.

How Do You Match Sensors with the Right Transmitter Board?

To make sure they fit well:

- See if your sensor sends analog (voltage/current) or digital signals.

- Verify that the transmitter’s input details fit the sensor’s output range.

- Assess site conditions like heat swings or dampness. For instance, our H509 capacitive level transmitter board has an isolation voltage up to 1000VDC between the sensor and the main circuit. This suits tough spots.

Best Practices for Integrating Sensors with a Process Control Board Transmitter

What Should You Check Before Connecting Sensors?

Before linking them up:

- Always review wiring plans and pin setups carefully.

- Confirm both the sensor and transmitter board have proper power.

- Pick shielded cables to cut down on electrical noise during signal sending.

Tips for Reliable Signal Transmission During Integration

Cable Management Techniques

Solid cable handling can determine your signal sharpness. Keep low-voltage signal wires clear of high-voltage ones. For analog signals, choose twisted-pair cables to boost resistance to noise.

Grounding and Shielding Best Practices

Ground shields at just one end to avoid ground loops. If your setup requires it, ground the transmitter board chassis right.

Calibration and Testing After Integration

After setup:

- Calibrate with known standard values.

- Use devices like multimeters or signal testers to check outputs.

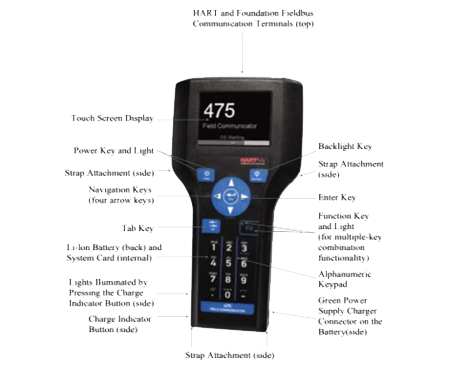

Our H475 Field Communicator simplifies calibration. It sets up and watches pipeline flow meters. This ensures exact measurement and better production standards.

Introducing ICwalk’s Range of Transmitter Boards for Your Needs

At ICwalk, we focus on delivering top-notch process control board transmitters made for your sensor linking needs. ICwalk transmitter boards earn trust from over 800 instrument makers in China. They have broad real-world testing.

Lo que hace ICwalk‘s Process Control Boards Stand Out?

Our items fully work with common protocols like HART and PROFIBUS-PA. They meet worldwide benchmarks, so integration goes smoothly and exports are simple. More than quality, we provide one-on-one tech help and fast shipping through our strong supply network.

Overview of ICwalk’s Product Lineup: Which One Fits Your Project?

Tabla del transmisor de temperatura

Our H648WD works best with RTDs or thermocouples. It changes them into a linear 4-20mA current isolated output. It includes cold junction compensation and 1000V isolation for firm work in rough conditions.

Placa del transmisor de presión

The H3051 series shines in pressure tasks. It pairs with unique sensors like PT100, magnetic flap, sapphire, and sputtered thin film types. Its strong anti-noise build keeps reliable function even in busy industrial areas.

tabla transmisor flujo

Our H837 micro-flow rotameter board gives accurate flow reading with 4 ~ 20mA signal output plus HART (2-wire). It serves fields like chemical handling, HVAC units, and water cleanup plants.

tabla transmisora nivel

For level detection, we have capacitive (H509) and ultrasonic (H760) choices. The H509 reaches high accuracy via Direct Digital Synthesis (DDS) tech. Meanwhile, the H760 offers touch-free liquid-level reading with temperature adjustment for steadiness in changing states.

Preguntas frecuentes

Q: How do I know if my sensor is compatible with a process control board transmitter?

A: Most transmitter boards note supported input types (e.g., RTD, voltage, current). Check your sensor’s output details and pair them with the board’s input range.

Q: Can I use multiple sensors on one transmitter board?

A: Some high-end boards handle multi-channel inputs. However, most are built for one sensor per channel to keep accuracy—review your model’s guide.

Q: Why is my signal fluctuating after connecting the sensor?

A: Shifts might come from bad grounding, electrical noise, or wrong wiring—recheck links and think about shielded cables.

At ICwalk, we commit to making industrial automation sharper and easier to reach. Whether you build custom tools or grow production, our process control board transmitters bring the accuracy, dependability, and adaptability you require. Teaming with ICwalk means you get not just excellent board options, but also a focused group aimed at your wins.

Publicaciones relacionadas

-

Integrating Sensors with a Process Control Board Transmitter: Best Practices for Reliable Signal Transmission

January 30,2026

-

How Is Signal Processing Achieved in Flow Transmitter Circuit Boards?

January 23,2026

-

Field Communicator vs. Traditional Handheld Tools in Industrial Maintenance

January 29,2026

-

¿Qué desafíos se resuelven mediante el uso de placas de transmisor de presión avanzadas?

Enero 22,2026

-

Factores clave a considerar al seleccionar un transmisor de placa de control de procesos

Enero 16,2026